Aerospace & Defense

The market calls for weight savings to improve fuel efficiency and reduce greenhouse gas emissions. Among the series of advanced engineering plastics and general engineering plastics provided by Hony Plastic Advanced Materials, some high-specific-strength materials with resistance to industrial chemicals, temperature resistance, wear resistance, and high-efficiency processing are used in this field.

Our technical service and development team can guide you when selecting our materials to ensure you get the best and most cost-effective solution.

Advantage

Reduce component weight, improve fuel efficiency, and increase payload

No galvanic corrosion when in contact with carbon fiber composites

Reduced friction, requiring little or no lubricant on friction surfaces

High abrasion resistance, superior to other polymers

Thermal insulation of critical electronic components and other structures

Good corrosion resistance to all general aviation hydraulic fluids

Provides a cost-effective alternative to aluminum, titanium and other metals

Serve

Hony Plastic serves industries and customers around the world. For main contractors, first-tier and second-tier suppliers, we provide a full range of material

discussions and application assistance. Our solutions are implemented through the supply of semi-finished profiles, near-net profiles,

or finished components through our technical centers processing partners.

We can ensure that products are in place when you need them.

Application

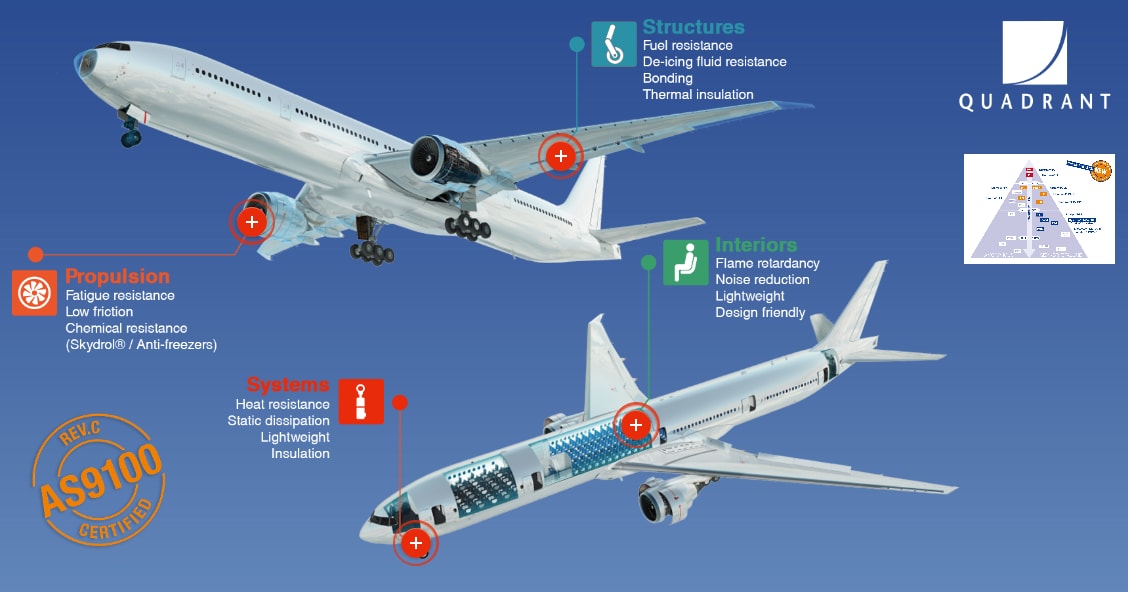

Airplane

Hony Plastic provide Mitsubishi Chemical Advanced Materials' materials which are found in all types of aircraft: fixed wing, rotary wing; commercial, military;

corporate, private; manned, unmanned.Whether it is components with wear-resistant surfaces, bushings for special shut-off devices, or seals for hydraulic systems,

Mitsubishi Chemical Advanced Materials' materials are used in a wide range of applications.

Every major system within an aircraft can benefit from the enhanced properties of materials from Mitsubishi Chemical Advanced Materials.

Cabin and Engine

The engine's external surface temperature can exceed 350°C, which is typically the hottest part of an aircraft.

Airplanes typically cool their surfaces with cold air during flight, however, reverse thrust during landing can result in hot air.

We provide high temperature resistant materials to meet the design requirements of engineers and designers for this part.

Product

Application

Duratron®CU60 PBI

Thermal Insulators High and Temperature Bushings

Duratron®PI Duratron®PAI

High temperature bushings and brackets

Ketron®PEEK

Bushings, friction surfaces, fuel pipes

Techtron®PPS

Bushings, friction surfaces, fuel pipes, brackets

Fluorosint®500 Fluorosint®HPV

Seals, Gaskets

Landing device

Whether the main or nose gear, this major system in an aircraft is where turbulence-induced vibrations are most severe. While the typical operating temperature range is between -40 °C and 70 °C, temperatures near the brakes can exceed 650 °C. Mitsubishi Chemical Advanced Materials can provide a series of lightweight, outstanding high-temperature change resistance, self-lubricating, shock-resistant, chemical-resistant and wear-resistant materials.

Product

Application

Nylatron®

Bracket, friction surface

Ketron®PEEK

Bushings, sealing rings, friction surfaces

Techtron®PPS

Bushings, friction surfaces, brackets

Fluorosint®500

Seals, Gaskets

Fluorosint®HPV

Duratron®CU60 PBI

Thermal insulators, high temperature bushings

Duratron®PI

High temperature bushings and brackets

Duratron®PAI

Wing and Control System

The wings are the parts that control the lift and roll of the plane. Hydraulic actuators control the flaps and ailerons on the wings, the rudder on the vertical stabilizer and the elevator on the horizontal stabilizer. Materials from Mitsubishi Chemical Advanced Materials are used in friction plates on control surfaces, seals in actuators, and ducts in deicing systems.

The fuel tanks are also inside the wings. We offer materials resistant to aviation fuel and used in pump valves. Antistatic materials are also available upon request.

Product

Application

TIVAR®UV

Sliding pad

Nylatron®GS

Friction surface, guide block

Ketron®PEEK

Bushing, sealing ring, friction surface, oil pipe

Techtron®PPS

Bushings, friction surfaces, oil pipes, brackets

Fluorosint®500

Seals, gaskets, seats

Fluorosint®HPV

Duratron®PAI

Inlet sealing ring, oil pipe, pump bushing

Built-in and built-in systems

Any configuration within the aircraft fuselage, such as: air conditioning systems (HVAC), fresh water and wastewater systems, cargo systems, or luggage racks, seats, service carts, and flaps in the passenger cabin, can be considered interior.

Mitsubishi Chemical Advanced Materials provides weight-saving, chemical-resistant, flame-retardant, smoke-free, and non-toxic materials for today's aircraft interiors.

Product

Application

Ketron®PEEK

Bushings, friction surfaces, rollers, tubes, brackets

Techtron®PPS

Bushings, friction surfaces, rollers, tubes, brackets

Fluorosint®500

Tube seals, gaskets

Fluorosint®HPV

Duratron®PAI

Bushings, fastening parts