Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

acrylic has a high degree of transparency, light transmission rate of 92%, "plastic crystal" reputation. And has excellent weather resistance, especially for outdoor applications, the crown of other plastics, and both good surface hardness and gloss, processing plasticity, can be made into a variety of shapes and products needed. Another sheet of a wide variety of color (including translucent color plate), another feature is that the thick plate can still maintain a high degree of transparency.

Acrylic products are also called plexiglass products, in different industries have a wide range of applications, in our daily life, acrylic products are also everywhere, in recent years the acrylic processing technology is constantly innovating and progressing, then how to acrylic processing? Here is a brief introduction:

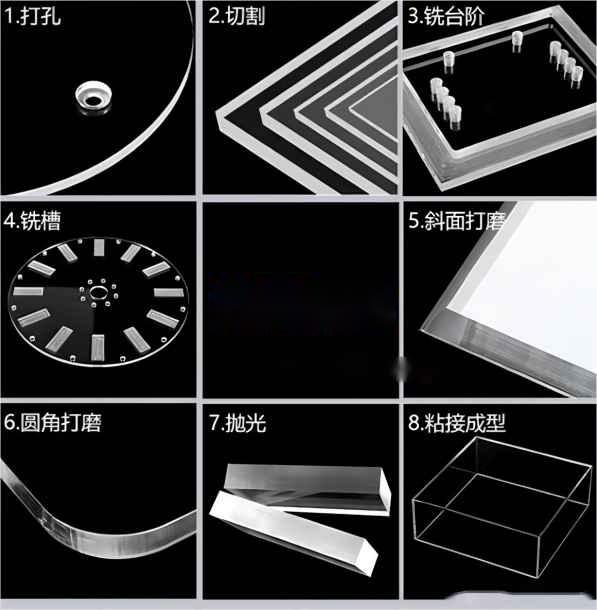

1, Cutting: acrylic sheet can be cut using manual or automatic cutting machine. Cutting to ensure that the saw blade is sharp, moderate speed, to avoid melting or cracks.

Acrylic processing will generally choose the laser cutting approach, this approach can be flexible cutting of acrylic raw materials, can be cut into different shapes, can be cut into different fonts and patterns according to the needs of different customers, but also can be made into different furniture. In addition, laser cutting acrylic raw materials can also make different signs and trademarks, in the advertising industry can play a role in publicity.

2, Drilling: acrylic plate can be drilled using a drill. Drilling should choose the right drill bit, moderate speed, to avoid overheating leading to melting or rupture.

Acrylic processing is also often used in the processing of perforation, acrylic itself has good processing characteristics, the use of laser cutting machine for perforation, to achieve a very high degree of accuracy of the perforation, in the perforation before the need for pattern design on the computer, and then through the laser cutting machine according to the design program, the processing of perforation on the acrylic material, the design is very important to do a good job in advance, you can reduce the bad finished product Appearance.

3, Polishing: you can use the polishing machine, grinding wheel, cotton wheel and other tools to polish the surface of the acrylic plate to improve the surface finish. Polishing should pay attention to moderate speed, avoid overheating.

Acrylic material itself has a very good transmittance, plexiglass processing plant can be acrylic depth polishing, can improve the transparency of acrylic products, after polishing the surface of the acrylic products will be very smooth, can improve the appreciation of acrylic products, through the polishing of acrylic can be made into handicrafts.

4, Hot bending: the use of hot air guns, hot bending machine or other heating equipment will be heated to a certain temperature of the acrylic plate, after bending. In the heating process to maintain a uniform temperature, to avoid localized overheating caused by deformation or bubbles.

Acrylic processing can use hot bending production and processing technology, acrylic material after heating to a certain temperature, it will melt, you can use the heating of acrylic material shape processing transformation, you can achieve different shapes of acrylic products, hot bending technology can be achieved using different methods, generally using hot bending machine and shaped mold for hot bending processing, hot bending angle can be adjusted according to the mold to achieve angle control! In order to realize the different shapes of acrylic products, to meet the needs of customers in different industries.

5, Engraving: acrylic plate can be engraved by engraving machine or laser engraving machine, to achieve a variety of patterns and text. Carving should choose the appropriate tool and parameters to avoid damaging the material.

6, Bonding: you can use a special acrylic adhesive to bond the acrylic sheet. When bonding to ensure that the contact surface is clean and flat to improve bonding strength.

Benefit of Acrylic Customized Processing In Hony Plastic

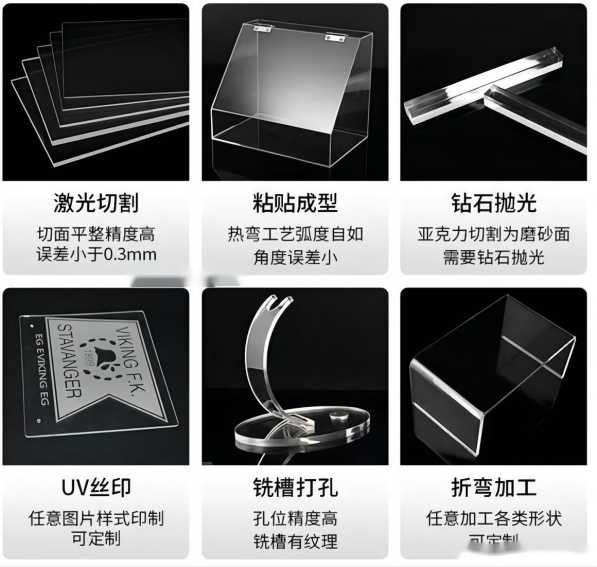

1. Laser cutting: the cutting surface is flat with high precision, the error is less than 0.1mm.

2. Paste molding: hot bending process arc freely, small angle error

3. Diamond polishing: acrylic cutting for the frosted surface, need diamond polishing

4. UV screen printing: any picture style printing, can be customized

5. Milling and punching: high precision holes, milling slots with texture

6. Bending processing: any processing of various shapes, can be customized

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.