Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

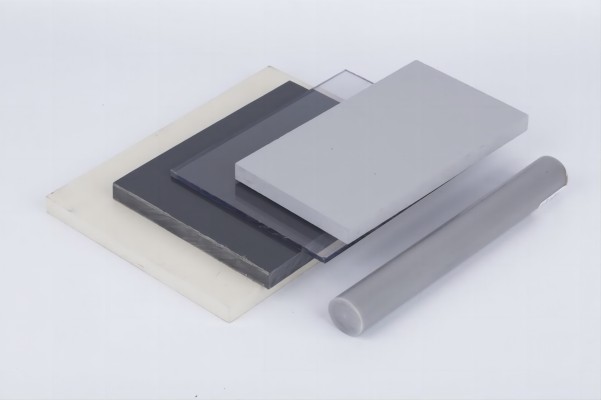

PVC (polyvinyl chloride)

Chemical and Physical Properties: Rigid PVC is one of the most widely used plastic materials. pvc is a non-crystalline material. pvc is often used with stabilizers, lubricants, auxiliary processors, colorants, impact agents and other additives. pvc has non-flammability, high strength, resistance to climatic changes, and excellent geometrical stability. pvc is highly resistant to oxidizing agents, reducing agents, and strong acids. PVC is highly resistant to oxidizing agents, reducing agents and strong acids. However, it can be corroded by oxidizing acids such as concentrated sulfuric acid, concentrated nitric acid and is not suitable for use in contact with aromatic hydrocarbons and chlorinated hydrocarbons.The glowing temperature of PVC is a very important process parameter when processing, and if this parameter is not appropriate, it will lead to the problem of material decomposition.The fluidity of PVC is quite poor, and the process range of PVC is very narrow. Especially large molecular weight PVC material is more difficult to process (this material usually need to add lubricants to improve the flow characteristics), so usually used are small molecular weight PVC material.PVC shrinkage is quite low, generally 0.2 ~ 0.6%.

A. Is the world's largest production, the most widely used plastics, its production accounted for 30% of the world's plastics

B. Its structure is a long chain structure or branched chain structure, is a typical crystalline polymer

C. Wuchang non-toxic odorless flammable white powder, the appearance of floating white

D. Excellent electrical insulation properties, suitable for high-frequency cable insulation layer

E. High chemical stability

F. Good low-temperature resistance, can be made of agricultural film, packaging bags

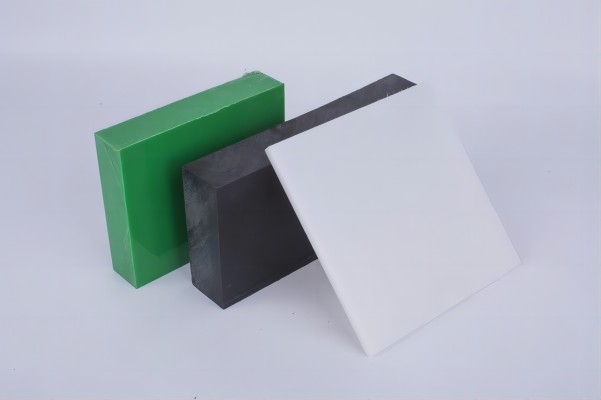

PE-HD (high-density polyethylene, commonly known as hard soft rubber, Kailex)

Resistance to wrinkle cold and heat poor mechanical strength, high hardness, good cold resistance, low heat distortion temperature, abrasion resistance, impermeability.

The most prominent excellent electrical insulation, engage in chemicals are better than high-pressure polyethylene, solubility is also better than high-pressure, room temperature is almost not any solvent (except for a few solvents can make it soften, plus gum decomposition, acid, alkali (except strong nitric acid), dielectric properties (with temperature, humidity, frequency is not related to)

Moisture absorption is small, do not need to dry, good mobility and sensitive to pressure changes, heating time is long for the occurrence of decomposition burns, slow cooling, molding and division long shrinkage range and shrinkage value is large, suitable for high-pressure injection, not suitable for straight gate, soft and easy to release the mold.

Chemical and physical properties: PE-HD's high crystallinity leads to its high density, tensile strength, high-temperature twisting temperature, viscosity, and chemical stability.PE-HD has a stronger resistance to penetration than PE-LD.PE-HD's impact strength is lower.PE-HD's properties are mainly controlled by density and molecular weight distribution. The molecular weight distribution of PE-HD suitable for injection molding is very narrow. For the density of 0.91~0.925g/cm3, we call it the first type of PE-HD; for 0.926~0.94g/cm3, we call it the second type of PE-HD; for the density of 0.94~0.965g/cm3. we call it the third type of PE-HD. the material has very good flow characteristics, with the MFR of 0.1 to 28. the higher the molecular weight, the more the PH-LD has the lower the impact strength. The higher the molecular weight, the poorer the flow properties of PH-LD, but it has better impact strength.PE-LD is semi-crystalline and has a high shrinkage after molding, between 1.5 and 4%.PE-HD is susceptible to environmental stress cracking. Cracking can be reduced by using materials with very low flow characteristics to reduce internal stress, PE-HD is easily dissolved in hydrocarbon solvents when the temperature is higher than 60 degrees Celsius, but its resistance to dissolution is somewhat better than PE-LD.

PE-LD (low density polyethylene, commonly known as soft rubber, flower material, tube material)

Low mechanical properties, softness, elongation, impact resistance, light transmission and other specific gravity, low-pressure polyethylene is good, a large number of hormone used as packaging film, sheet, packaging containers, coatings, wire and cable wraps and soft injection molding, extrusion parts.

Excellent electrical insulation properties and chemical resistance, plus gum decomposition, acid and alkali resistance (except strong nitric acid), good dielectric properties. Easy to mold.

Chemical and physical properties: the density of commercial PE-LD material is 0.91~0.94g/cm3. PE-LD is permeable to gas and water vapor. the coefficient of thermal expansion of PE-LD is very high unsuitable for processing of long-term use of products. If the density of PE-LD is between 0.91~0.924g/cm3, then its shrinkage rate is between 2-5%; if the density is between 0.926~0.94g/cm3, then its shrinkage rate is between 1.5%~4%. The actual current shrinkage rate also depends on the injection molding process parameters.PE-LD is resistant to a wide range of solvents at room temperature, but aromatic and chlorinated hydrocarbon solvents can cause it to swell. Similar to PE-HD, PE-LD is susceptible to environmental stress cracking.

PP (Polypropylene, commonly known as polypropylene)

It is one of the most heat-resistant general-purpose plastics, with high yield strength and high bending labor life. Shrinkage is large, impact strength changes with temperature, rigidity is insufficient, flammable.

Stable chemical properties, good dielectric properties, has a good high chemical impregnation, can withstand 80 degrees below the inorganic acids, alkalis, salts and many organic solvents immersion, water absorption is also very little.

It has good fluidity under the melting point and good molding performance.

Chemical and physical properties: PP is a semi-crystalline material, it is harder than PE and has a higher melting point. Because homopolymer-type PP is very brittle at temperatures above 0 degrees Celsius, many commercial PP materials are irregular copolymers with 1 to 4% ethylene or higher-ratio ethylene-containing pincer-break copolymers. Copolymer-type PP materials have lower heat distortion temperatures (100 degrees), lower transparency, and lower rigidity, but have greater impact strength.The strength of PP is stronger as the ethylene content increases.PP has a card softening temperature of 150 degrees. Because of the high crystallinity, this kind of vegetable two oh the surface stiffness and scratch resistance characteristics are very good.PP does not have environmental stress cracking problem. Usually, PP is modified by glass fiber, metal additives or thermoplastic rubber. For the same MFR, the copolymer type is stronger than the homopolymer type. Due to crystallization, the shrinkage of PP is quite high, typically 1.8 to 2.5%. And the directional uniformity of shrinkage is much better than materials such as PE-HD. Adding 30% glass additive can reduce the shrinkage to 0.7%. Both homopolymer-type and copolymer-type PP materials have excellent resistance to moisture absorption, acid and alkali corrosion, and solubility. However, it has no resistance to aromatic hydrocarbon (e.g., benzene) solvents, chlorinated hydrocarbon (carbon tetrachloride) solvents, etc. PP also does not have oxidation resistance at high temperatures like PE.

PPE Polypropylene Ethylene

Chemical and Physical Properties: Typically, commercially available PPE or PPO materials are generally blended with other thermoplastic materials such as PS, PA, etc. These blends are still referred to as PPE or PPO. These blends are still generally referred to as PPE or PPO. blended PPE or PPO has much better processing characteristics than the pure material. The variation in properties depends on the ratio of the blends such as PPO to PS. Blended materials with Pa66 have a higher chemical stability at higher temperatures. The material has very low hygroscopicity and the products have excellent geometrical stability. The PS blends are non-crystalline, while the PA blends are crystalline. Shrinkage can be reduced to 0.2% by adding glass fiber additives. The material also has excellent electrical insulation properties and a very do coefficient of thermal expansion. The viscosity depends on the ratio of the mixture in the material, and an increase in the ratio of PPO leads to an increase in viscosity.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.