Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

FR4 Epoxy glass cloth laminate, it is to alkali-free glass fibers, by shearing, settling, bonding, baking and other processes made of non-woven fabrics called glass fiber mat or non-woven; its structure is sparse, good permeability, isotropic, and glass cloth, compared with the process is simple and inexpensive. To alkali short-cut glass fiber mat as reinforcing material, dipped in epoxy adhesive made of pre-impregnated material pressed into the epoxy glass mat laminated products, with excellent mechanical properties and processability, commonly used to manufacture support and used as a fixed piece for large-scale turbine generator windings end fixed. Overcome the metal fixing parts and easy to occur creepage phenomenon, thus greatly improving the reliability of large generator operation.

HONY Plastic FR4 epoxy fiberglass cloth laminate is a rigid board insulation material made of alkali-free fiberglass cloth impregnated with epoxy resin and hot-pressed, which is subdivided into different grades such as EPGC201, EPGC202, EPGC203, EPGC204, EPGC306, EPGC308, etc. in IEC standard; and G10, FR-4, G11, FR-5 and other grades in NEMA (U.S. National Electric Manufacturing Association) standard. industry) standards are divided into G10, FR-4, G11, FR-5 and other grades.

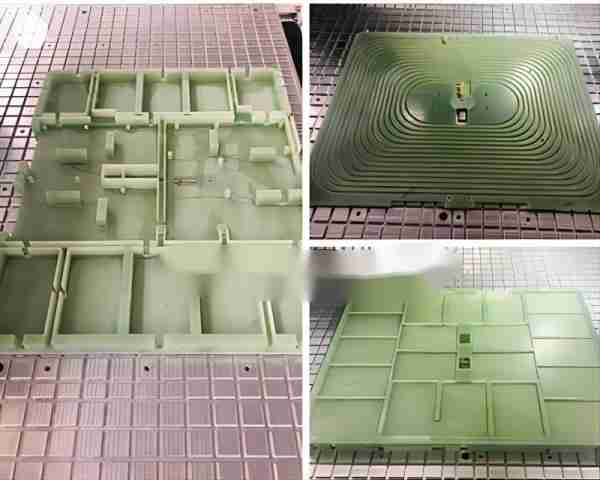

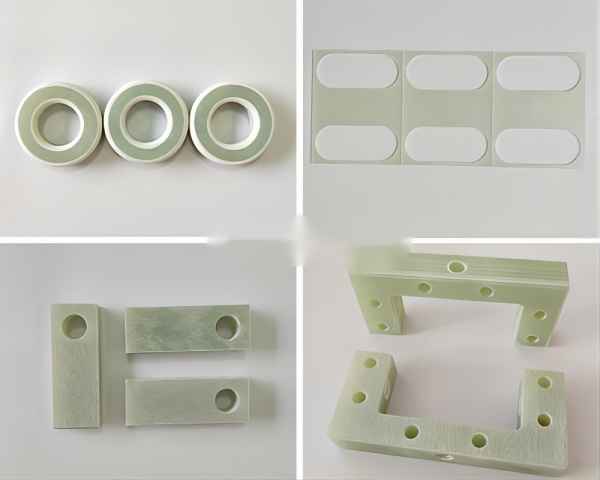

FR4 Epoxy fiberglass cloth laminate has the following properties: good electrical properties under high humidity environment, good mechanical properties under medium temperature, flame retardant (FR series), voltage resistance, stable product quality and so on. It can be processed into various parts by lathe machining, stamping, trimming, drilling, sandblasting, grinding, sawing and milling. Epoxy fiberglass cloth laminate is widely used in electric motors, electrical equipment, circuit breakers, switchgear, transformers, DC motors, AC contactors, explosion-proof electrical appliances, traveler wheels, low-voltage electrical insulating separators, etc., in the fields of electrical, electronics, automotive industry, medical care and so on.

HONY Plastic has fifteen years of experience in the industry, and has various series of processing equipment, including machining centers, CNC grinding machines, CNC lathes, CNC milling machines, bending machines, surface treatment stamping equipment and so on. Able to provide insulating material parts processing services, with stable and flexible processing capabilities to meet the needs of rapid sampling, high precision price and low-cost mass production.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.