Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

In the age of booming automation, 4-axis machining has paved the way for a variety of manufacturing processes. Understanding the intricacies of this automation marvel is interesting, complex, but vital.

What is 4-axis machining?

Often referred to as 4-axis CNC machining, 4-axis machining is a multi-axis machining process that utilises CNC machines equipped with additional rotary axes.

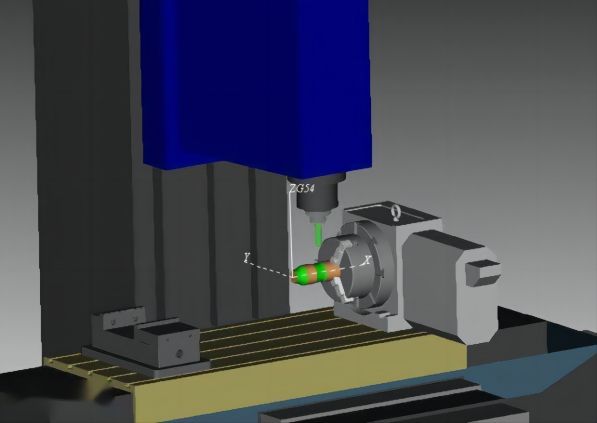

The process involves a CNC machine that moves in four different axes simultaneously. It typically involves X, Y, and Z (three linear axes) and an additional axis, the A-axis, which is a rotary axis around the X-axis. This unique feature allows the machining of complex parts and milling at strange angles that are not possible with 3-axis machining.

CNC stands for Computer Numerical Control.

The X, Y and Z axes are the three mutually perpendicular directions.

The A-axis provides the ability to rotate the workpiece around the X-axis.

4-Axis CNC Machining Process

Understanding the process of 4-axis CNC machining requires focusing on the motion and functionality of CNC machines. These machines work seamlessly, moving the cutting tool along the X, Y, and Z axes while rotating the workpiece along the A-axis. This additional axis allows the machine to manipulate the workpiece from different angles and helps to accurately manufacture complex parts.

Steps in 4-axis CNC machining

CAD Design: The product is first designed using Computer Aided Design (CAD) software. Designers typically use a Windows PC to complete this process.

CAM Path: Once the design is complete, the Computer Aided Manufacturing (CAM) software creates the tool path that the CNC machine will follow.

Setup: The part is mounted on the CNC machine and the machine is set up with the appropriate cutting tools.

Machining: The machine then begins the machining process. It moves in the X, Y and Z directions while the mounted workpiece rotates in the A-axis, allowing continuous machining at different angles.

Finishing: Once the machining process is complete, any necessary finishing operations are performed, such as cleaning or deburring

What types of 4-axis CNC machine tools are available?

There are several types of 4-axis CNC machines, each with unique features and suited to different applications.

Milling Machines

These are probably the most commonly used 4-axis CNC machines. They are great for creating complex parts with features such as angled cutouts and holes. The additional A-axis allows the cutting tool to approach the workpiece at an angle, allowing for the ability to mill slots and holes at any desired angle.

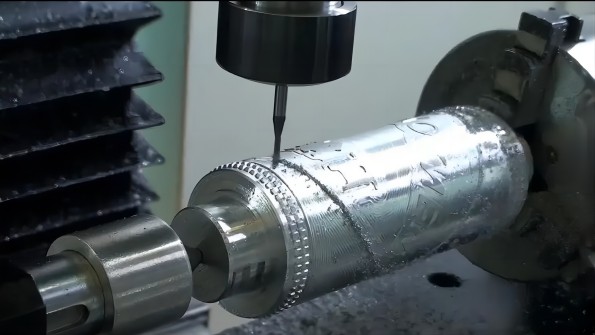

Lathe

4-axis CNC lathes are used for turning operations. The added axes allow the lathe tool to approach the workpiece at any angle, enabling complex geometries to be created. Lathes can work with a wide range of materials such as metals, wood and plastics, offering a wide range of manufacturing possibilities.

Routers

Primarily used in the woodworking industry, 4-axis CNC routers offer precision and the ability to machine large parts. Their robust construction and simple setup make them a valuable asset to any production line.

Applications of 4-axis CNC machine tools

4-axis CNC machines have a wide range of applications due to their ability to manufacture complex parts and components. Here are a few areas where these machines have had a significant impact:

Aerospace industry: 4-axis CNC machines are widely used in the aerospace industry due to their high precision and ability to handle complex geometries. They can manufacture complex parts, such as turbine components and airframe parts, with high precision and speed.

Automotive: From engine components to body parts, the automotive industry relies heavily on 4-axis CNC machining for production. The ability to work at odd angles and efficiently produce complex parts makes them a staple in this industry.

Electronics industry: the manufacture of electronic components requires a high degree of precision. 4-axis CNC machines can achieve this by creating components such as circuit boards and housings.

Oil and gas industry: the oil and gas industry requires parts that can withstand extreme conditions. 4-axis CNC machines can achieve this by creating high quality, durable components.

Benefits of 4-Axis CNC Machining

4-axis CNC machining offers a range of advantages that increase efficiency and provide cost-effective solutions for a variety of manufacturing industries. Here are some of the notable advantages:

Enhanced functionality: the additional A-axis allows for the creation of more complex parts that would be difficult to achieve with 3-axis. This opens up new possibilities for design and manufacturing.

Increased efficiency: By allowing continuous machining from different angles without the need to manually adjust the workpiece, 4-axis CNC machining can significantly reduce production time.

Higher precision: The additional axes allow for better control of the machining process, resulting in increased precision and accuracy.

Versatility: from small electronic parts to large aerospace components, 4-axis CNC machines can handle a wide range of materials and part sizes, making them versatile tools in any manufacturing setup.

Disadvantages of 4-axis CNC machining

While the advantages of 4-axis CNC machining are obvious, it is important to acknowledge some of its limitations.

High setup costs: purchasing and setting up a 4-axis CNC machine can be very expensive, which is a major investment for any business. However, considering the efficiency and functionality it offers, this investment can pay off in the long run.

Requires skilled operators: While CNC machines can automate most tasks, they still require skilled operators to set up, programme and supervise them. This adds to the cost and complexity of the operation.

Limited by geometry: While the additional A-axis provides greater flexibility, 4-axis machines may still struggle to handle some geometries and angles. In this case, a 5-axis CNC machine may be a more suitable option.

Conclusion

In conclusion, 4-axis CNC machining is a complex process that offers greater efficiency, versatility, and precision than 3-axis machining. While it has some limitations, the benefits usually outweigh these.

This technology has revolutionised industries ranging from aerospace and automotive to electronics and oil and gas by creating complex parts with high precision and speed. As technology continues to advance, the capabilities of these machines will only increase, further cementing their integral role in modern manufacturing.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.