Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is Polyphenylene Sulfide ?

Full name polyphenylene sulfide resin, PPS structure symmetrical asexual, small water absorption, low shrinkage, electrical insulation is very good high temperature plastic; PPS resin and glass fiber, inorganic fillers, aramid fibers, metals, and carbon fibers have a very good affinity, so it can be produced to enhance the composite materials or alloys; Pure PPS specific gravity (PPS density) of 1.34, reinforced by fiberglass can be 2.0 Above; is a white or brown (dark brown) plastic, flame retardant fire UL94V0-5VA grade; PPS has a very high rigidity and bending strength, creep resistance is good, with the rigidity and strength of the metal (the product falls to the ground with a metal crisp sound); PPS melting point of 286 ° C degrees, the heat distortion temperature of 260 ° C - the heat distortion temperature of 280 ° C degrees, the long term heat resistance of 200 ° C and above. Can be over high temperature reflow soldering, wave soldering and ultrasonic welding.

The advantage of Polyphenylene sulfide PPS

Polyphenylene sulfide PPS good resistance to chemicals, acid and alkali corrosion, good oil resistance; PPS weathering, radiation resistance, good aging resistance, good dimensional stability, can work in high temperature and high humidity and heat environment, high temperature and low temperature resistance, good cold resistance; PPS good abrasion resistance, coefficient of friction is small, especially in the inside of the addition of PTFE (Polytetrafluoroethylene / teflon) and graphite wear-resistant materials, you can greatly enhance the wear resistance and resistance to abrasion. PPS wear resistance and abrasion resistance; PPS dielectric constant is small, good insulation.

The application of PPS

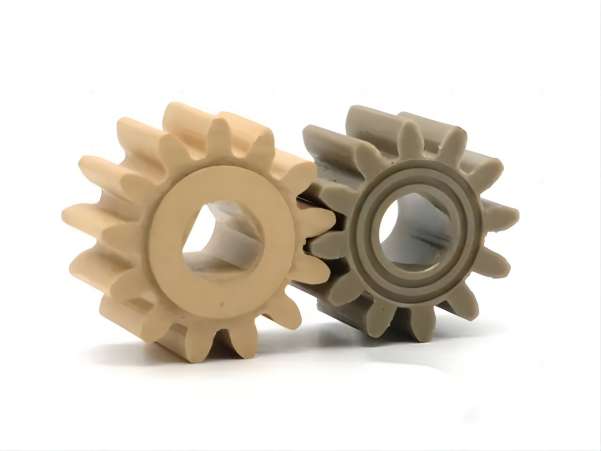

The application of PPS is centered on its excellent heat resistance, taking into account its friction-reducing and self-lubricating properties, chemical stability, dimensional stability, flame retardancy and electrical insulation. In the chemical industry PPS can be used for synthesis, transportation, storage of materials, reaction tanks, pipelines, valves, chemical pumps, etc., in the mechanical center PPS can be made impellers, blades, gears, eccentric wheels, bearings, clutches and wear-resistant parts; PPS's main use is still in the field of electronic and electrical appliances, such as the production of transformer skeleton, high-frequency coil skeleton, plugs, sockets, wiring harnesses, contactor drum drums, and various precision parts, etc.

Electronic and electrical appliances: micro electronic components package, connectors, connectors, sockets, coil skeleton, motor shells, electromagnetic regulator disk, TV high-frequency head shaft, relays, fine-tuning capacitors, fuse holders, recorders, magnetic therapy and other parts. Also used in precision instruments: computers, timers, tachometers, copiers, cameras, temperature sensors, and a variety of test instruments shells and parts.

Automotive industry: PPS is used in the automotive industry accounting for about 45%, mainly used in automotive functional parts, ignition, heaters, clutches, transmissions, gearboxes, bearing brackets, lampshades, bumpers, fans, exhaust systems, as well as reflectors and lamp holders parts. It can be used instead of metal to make exhaust cylinder circulating valves and water pump impellers, pneumatic signal adjusters and so on.

What is the difference between the different proportions of glass fibers in the two materials PPSGF30% and PPSGF40%?

We all know that plastics made from PPS exhibit high Young's modulus, tensile strength and strain at break. And the height of the pyramid of plastics is usually related to cost, formability and performance. At the bottom of the pyramid, standard, engineering and high-performance plastics are included. Of these, plastics with high-performance properties, such as polyphenylene disulfide, lead this classification.

In the two materials PPSGF30% and PPSGF40%, we can see that Young's modulus is the same for them. However, in the direction from 0 to 90, the Young's modulus decreases by approximately 50%. In comparison, PPSGF40 is about 35% stiffer than PPAGF30. This has been presented with engineering strain and stress measurements. Since both materials are made from recycled materials, they are ideal for environmental efforts. In addition, both materials are easy to maintain because they are easy to clean. The orientation of the fibers determines a large part of the mechanical properties of SFRP.

Anyone looking for a high-quality and inexpensive material, 40% fiberglass filled material is a good choice. Nonetheless, this prevents chemical reactions that could damage the storage. Their calibration allows them to measure quantities with unmatched accuracy because of their calibrated design. Due to these features, they are popular among many users. The shear strength is calculated, and on the basis of the experimental results, we evaluate the differences in fiber orientation.

To compare the two materials, we utilized Young's modulus, strength and strain. These data were also used to calibrate the standard, PPS-GF40 material is extremely strong at high temperatures due to its glass fiber reinforced strength.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.