Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

About Screws in industry application ?

Screws this thing, life can be said everywhere, it plays a different role in all aspects of our lives, its role is small, but is an essential part of the use of the environment is also variable, PEEK (polyether ether ketone as a semi-crystalline thermoplastic high temperature clinker program plastics, due to the macromolecular chain contains rigid benzene ring, flexible ether bond and improve the intermolecular forces of carbonyl, structural regularity, and thus has high heat resistance, high strength, high stiffness, high fracture toughness and other excellent overall performance, can be well adapted to a variety of harsh environments. Therefore, it has high heat resistance, high strength, high stiffness, high fracture toughness and other excellent comprehensive performance, can be well adapted to a variety of harsh environments.

What are the advantages of PEEK as a screw?

We all know that the most important role of the screw is to connect the two parts together, so that it is fixed, which requires the screw material itself hardness to be hard, able to resist the pressure of mechanical operation, to maintain the stability of its dimensions, and the excellent strength and stiffness of the PEEK material is extremely resistant to high temperatures,, PEEK's long-term use of the temperature of about 260-280 ° C, the short-term use of the temperature can reach 330 ° C, and Resistant to high pressure up to 30MPa, at a temperature of up to 260 ° C can be used for a long time, but also does not occur deformation.

And PEEK has excellent chemical corrosion resistance, in addition to concentrated sulfuric acid, PEEK is insoluble in any solvent, has a high chemical stability, ordinary chemicals generally can not hurt it, corrosion resistance can be said and there is also a strong resistance to hydrolysis, such as oil, water, etc. It can not play any role, applicable to a variety of working conditions in harsh environments.

PEEK also has a good self-lubricating, easy to process and other excellent performance, in high-speed mechanical operation, with its own lubrication, reducing the loss of friction apparatus, PEEK material is also easy to process just in line with the screws of a wide variety of specifications varying demand, making it not only in the industrial manufacturing in a big way in the aerospace, automotive manufacturing, electrical and electronic, medical and food processing and other fields have a wide range of applications.

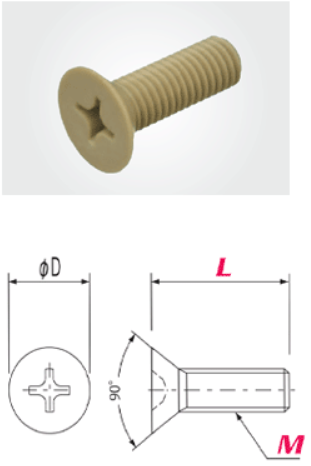

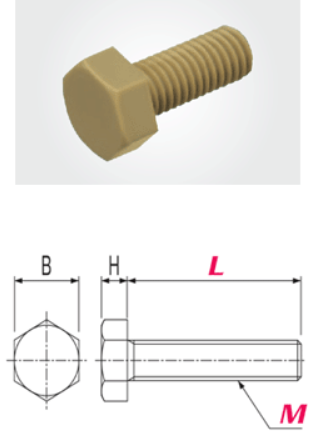

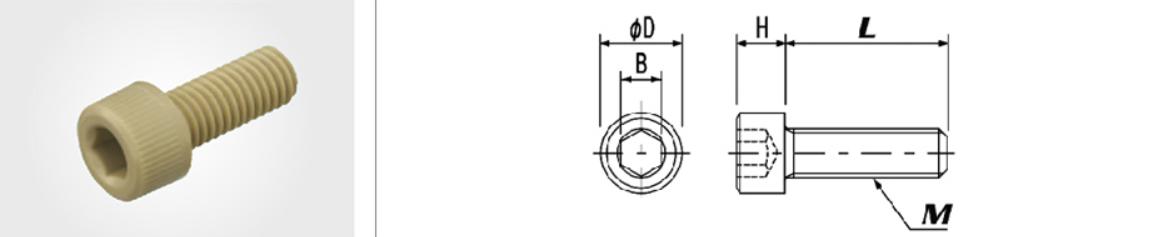

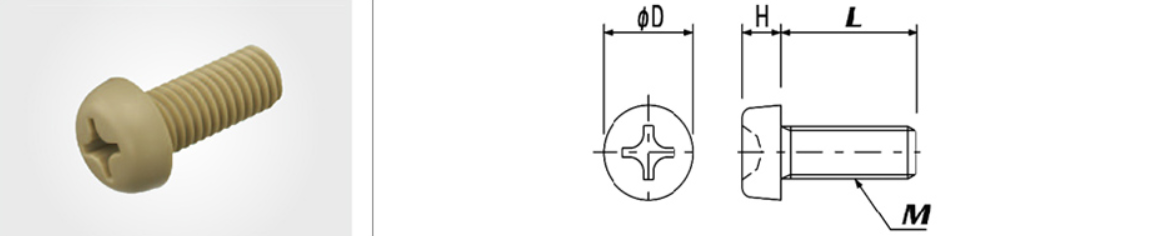

PEEK screws with PEEK as raw material, injection molding through the mold, thread precision of 6g, due to the excellent performance of PEEK material, PEEK screws compared to traditional nylon, PC, PP and other screws have the following characteristics:

1, Corrosion resistance, thanks to the excellent chemical resistance of PEEK materials, PEEK screws can withstand most of the corrosive solvents, corrosion resistance second only to fluoroplastics;

2, High temperature, PEEK screws long-term temperature 220 degrees;

3, High strength, excellent mechanical strength, M6 bolts can carry a load of more than 150KG;

4, Low temperature resistance, can be used in -50 ℃ environment;

5, Radiation resistance, can withstand ultraviolet light, steam, high dose of gamma rays;

PEEK screws compared to metal screws, although the mechanical strength is weaker, but in terms of insulation, weight reduction and other aspects of the metal screws can not be compared.

In the machinery and construction application market, a kind of special material named PEEK (polyether ether ketone) resin is widely used in the field of precision screws.PEEK resin precision screws have become the special fastening equipment in the machinery and construction industry because of its excellent performance and advantages. This article will introduce the advantages and applications of PEEK resin precision screws from six aspects.

1.Excellent fluidity and processing performance

PEEK resin precision screws have excellent fluidity and excellent processing performance. Its low melting point and high melting index makes PEEK resin can maintain good fluidity in the process, which is conducive to the molding and processing of screws. At the same time, PEEK resin has good abrasion resistance and fatigue resistance, making the processing of screws more stable and reliable.

2.Low water absorption and excellent hydrolysis resistance performance

PEEK resin precision screws have low water absorption and excellent hydrolysis resistance. Its low water absorption makes PEEK resin screws in a humid environment can also maintain stable performance, not easy to moisture deformation. At the same time, PEEK resin has good corrosion resistance, able to resist the erosion of acids and alkalis and other chemical substances, to extend the service life of the screw.

3.High impact strength and high rigidity

PEEK resin precision screws have high impact strength and high rigidity. Its excellent mechanical properties make PEEK resin screws can withstand large impact loads and static loads, suitable for a variety of mechanical and construction application scenarios. At the same time, PEEK resin has good elastic recovery, can be quickly restored to its original state after the force, improve the service life of the screw.

4.Excellent high temperature resistance

PEEK resin precision screws have excellent high temperature resistance. Its heat distortion temperature is high, can maintain stable performance in a high temperature environment. This makes PEEK resin screws have a wide range of applications in high-temperature working environments, such as automobile engines, aerospace and other fields.

5.Excellent flame retardant properties and high flame retardant grade

PEEK resin precision screws have excellent flame retardant properties and high flame retardant grade. Its non-combustible and self-extinguishing properties make PEEK resin screws can maintain a high level of safety in dangerous environments such as fire. This makes PEEK resin screws in the construction industry and other areas requiring high flame retardant properties are widely used.

6.PEEK resin precision screws have excellent mechanical strength, good hardness and rigidity

Its high strength and high hardness makes PEEK resin screws can withstand greater mechanical load and extrusion pressure, not easy to deform and fracture. This makes PEEK resin screws play an important role in connecting and fixing mechanical equipment and building structures.

PEEK resin precision screws with its excellent flow properties, low water absorption, high impact strength, high temperature resistance, flame retardant properties and mechanical strength and other advantages, become the mechanical and construction applications market special fastening equipment.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.