Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PEEK is one of the most high temperature resistant engineering plastics and also has the best overall properties: excellent high temperature resistance, wear resistance, high mechanical strength, corrosion resistance, low creep, and resistance to high temperature water vapour and excellent electrical properties.

Because of its excellent all-round properties, PEEK polyether ether ketone is widely used in the aerospace industry, the medical industry, the electronics industry, various machinery and equipment industries and the automotive industry.

Reducing the weight of automobiles has become a priority in order to reduce CO2 emissions. Seeking light weight, high strength and excellent fluidity of high temperature resistant materials to create a smaller and more reliable performance of the growing demand. PEEK has excellent mechanical properties and excellent chemical resistance to automotive fluids, good wear resistance and so on to make it more and more widely used in the automotive industry.

At present, such as BMW, Audi and other high-end car manufacturers have begun to subvert the traditional concept of thinking, the use of excellent performance of PEEK and other new materials and superb technical process for the development and design of new models.

As an advanced engineering plastic, PEEK plays an important role in weight reduction, effective extension of component service life and optimisation of component utilisation due to its good machinability, flame retardant, non-toxicity, abrasion and corrosion resistance, etc., but it is not yet widely known and fully applied. Many customers due to the lack of in-depth understanding and knowledge of PEEK, and do not know what specific

PEEK products can replace the automotive components?

PEEK polyether ether ketone in the automotive industry mainly has the following applications:

PEEK polyether ether ether ketone seals and thrust washers, used in automotive transmission and clutch seals;

PEEK polyether ether ether ketone worm gears, which are mainly used in automotive seat adjustment devices;

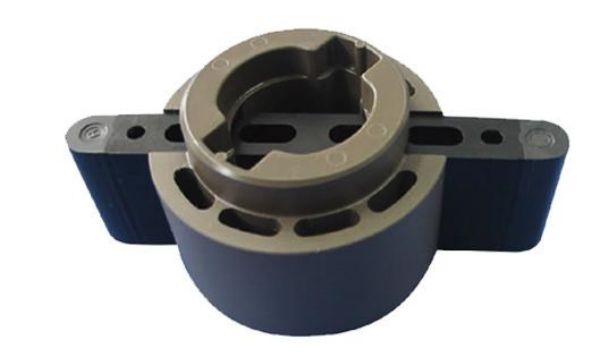

PEEK polyether ether ether ketone vacuum pump rotary discs, mainly used in booster brake systems for automobiles;

PEEK polyether ether ether ketone ABS cams and ABS spools, mainly used in brake systems of automobiles;

PEEK polyether ether ether ketone bushings and plain bearings, mainly used for window rocker motors and wiper motors and sunroof motors in automobiles;

PEEK polyether ether ether ketone limit pegs and limit shims, mainly used in window rocker motors and wiper motors and sunroof motors of automobiles;

PEEK sealing rings, mainly used in automotive compressor seals;

PEEK polyether ether ether ketone oil pump gears, PEEK polyether ether ether ketone balancing gears, PEEK polyether ether ether ketone gears and so on are mainly used in engine parts and suspension systems.

Advantages of polyether ether ketone PEEK in the automotive industry:

1, Heat resistance and strength is much higher than traditional plastics, the highest temperature resistance 260 ℃;.

2, PEEK by fibre reinforced tensile strength of up to 224Mpa, comparable to aluminium alloy;

3, To meet the automotive lightweight, energy and environmental issues, new safety standards;

4, Has very excellent mechanical properties at high temperatures, and can remain stable;

5, Has outstanding mechanical strength, impact resistance and wear resistance, can greatly improve the service life of parts;

6, Has excellent chemical resistance, excellent resistance to all automotive liquids, even at high temperatures, also has excellent resistance to acids, alkalis, inorganic and organic chemicals;

7, Excellent dimensional stability, low moisture absorption and low coefficient of thermal expansion, can meet the strict tolerance requirements of the parts.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.