Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

vespel is one of the most heat-resistant and wear-resistant of the high performance resins now available for mass production. It can be used under non-lubricated conditions (high PV value) at a height of 10 times or more without affecting other materials, and therefore will not cause any harm.

Vespel is a typical representative of the Polyimide (PI) plastic series.

VESPEL-SP1 (brown): Mechanical strength and electrical properties of the basic specification.

VESPEL-SP21 (black): A 15% graphite filled specification that provides abrasion characteristics and heat resistance.

Vespel SP-21 Sheet and Vespel Rod - DuPont Vespel SP-21 grade contains 15% graphite by weight to improve wear resistance and reduce friction for bearings, thrust washers, bushings, seals, sliders, and other applied wear applications. Vespel SP-21 has the highest mechanical properties of graphite filled grades. If insulation is not as important as low friction performance, then you are looking for graphite reinforced SP-21.

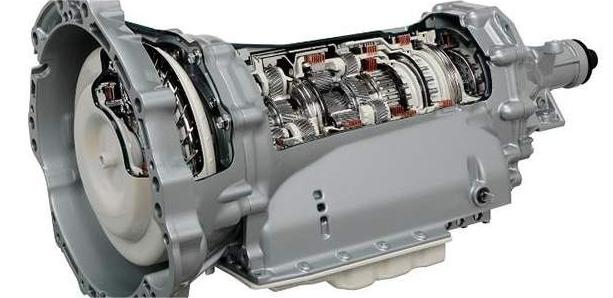

Thinner, lighter Vespel SP-21 thrust washers replace all-metal needle bearings in new 7-speed AT for rear-wheel-drive vehicles

Vespel thrust washers have been selected to replace the larger, heavier metal thrust needle bearings that sit between the clutch housing and the aluminum transmission case.

The Challenge

Good mileage, compact design and fun to drive!

With a footprint nearly identical to a 5-speed AT, JATCO Product's new 7-speed transmission creates an exciting driving experience for luxury-class rear-wheel-drive vehicles. the AT's superior response time delivers exhilarating acceleration and a quiet, laid-back experience based on the driver's desires, while also improving fuel efficiency. the new 7-speed transmission is designed to provide the driver with a more efficient driving experience than a 5-speed AT.

The Solution

Reduced size, weight and part count

Vespel SP-21 thrust washers are thinner and lighter than comparable metal thrust needle roller bearings, helping to reduce the overall size and weight of the AT. Vespel SP-21 thrust washers were also selected because they can rotate directly against the aluminum housing, reducing parts count and simplifying the assembly process.

Key Benefits

Excellent heat and wear resistance. Ability to make direct contact with aluminum components

Vespel thrust washers have demonstrated excellent reliability in transmission applications for many years for the following reasons:

No melting point means the washers will not melt

High ultimate PV value (wear resistance index) superior to other engineering resins

Low wear when used directly on lubricated aluminum parts, even in the presence of contaminants or foreign matter in the oil

Custom-designed oil grooves on the surface of the gasket allow for precise control of oil flow, further enhancing wear resistance.

Very low coefficient of friction due to easy formation of an oil film on its surface.

About DuPont™ Vespel® SP-3

Dupont™ Vespel® SP-3 is 15% moly-filled (molybdenum disulfide solid lubricant) for wear and friction resistance in vacuum and other moisture-free environments where graphite becomes abrasive. The best wear performance for this product is within dry environments.Vespel ® SP-3 is for wear and friction resistance in vacuum and other moisture-free environments where graphite actually becomes abrasive.

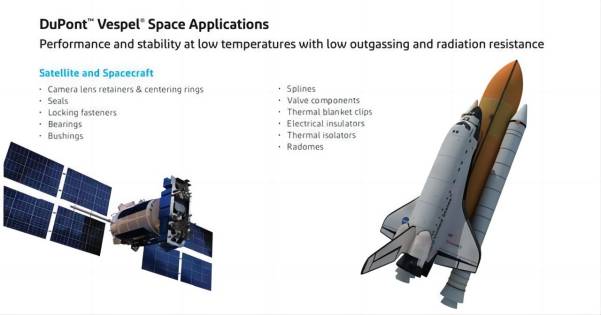

DuPont™ Vespel® SP-3 for Spacecraft Applications

DuPont™ Vespel® SP-3 has been widely used for spacecraft applications since the early days of space exploration. Vespel® SP-3 is often specified for bearings, bushings, rollers, and slide pads that require superior friction and wear performance in vacuum conditions. The advantages of DuPont™Vespel® for spacecraft

Applications include:

Excellent friction and wear characteristics in vacuum

Maintains ductility and moderate modulus throughout a broad temperature range - from cryogenic to elevated temperatures

Excellent flammability characteristics

Good dimensional stability - low and consistent thermal expansion coefficient throughout a wide operating temperature range

Low outgassing

Vespel SP-3 parts and profiles are suitable for seals and bearings in vacuum or dry environments.

Reliable under extreme conditions

Vespel parts and profiles for harsh industrial operating environments

Extreme temperatures, high friction and heavy loads? Since 1965, Vespel has outperformed other engineered materials in harsh conditions.

Demanding applications such as aerospace components, semiconductor processing, automotive manufacturing and energy production rely on Vespel parts to keep their equipment running.

Vespel polyimide materials offer continuous operation from low to high temperatures; low wear and friction at high PV in lubricated or unlubricated environments; excellent creep, strength and impact resistance; excellent dimensional stability; low coefficient of thermal expansion; and ease of processing.

Vespel's ability to make parts lighter in weight is not only practical, but in many cases superior to general-purpose metals, ceramics and other engineering polymers such as PEEK (polyether ether ether ketone) and PAI (polyamide-imide).

In design centers in Asia, Europe and the Americas, DuPont technicians work with customers to combine materials science and design to produce high-performance parts and keep production running smoothly.

Vespel components and profiles, whether customized or conventional, have been tested and proven reliable in demanding applications around the world. They come in sheet, bar, tube, square, long, disc, ring, ball and custom machined parts.

The Challenge

Sealing is critical to preventing leakage in critical components, such as valves, pumps and pipes.

such as valves, pumps and pipes. They must endure an environment that challenges their continued reliability. Metal-to-metal seals are costly to manufacture, requiring hard surface finishes and multiple grinding steps to achieve low leakage rates - Increasingly demanding environments and pressures, such as high temperatures, while maintaining adequate compression strength and creep resistance for seal life - Most engineering plastics deteriorate rapidly at high temperatures or are unable to withstand the heat. most engineering plastics deteriorate rapidly at high temperatures or are unable to withstand thermal cycling.

Sealing components made from Vespel

The SP and SCP families of products enable a combination of features to meet demanding applications.

Vespel SP and SCP components provide consistent performance Maintenance of tight seals over a wide range of temperatures High compressive strength and low creep rates allow for long runs Low coefficients of friction between pressure fits and low wear rates Surfaces produce longer part life and cleaner environments (bearing grades)

Vespel SP and SCP parts and shapes can be machined to close tolerances and seal surface finishes using traditional methods of machining technology.

Applications

Bearings, bushings, insulators, seals, thrust washers and wear rings

Wear pads, wear strips and pipe clamps

Thermoplastic injection molded, assembled and composite parts

Test sockets and wafer guides

Glass clamping technology

Wear parts in centrifugal pumps

Hydrocarbon, chemical and feed pumps

Drinking water applications

Advantages

Lightweight but able to withstand high loads

Chemical, electrical, wear and heat resistant

Strength, rigidity and dimensional stability

Easily machined to very tight tolerances

Effective in extreme vacuum, radiation, oxygen compatibility, cryogenic conditions, and exposure to flame

Lower manufacturing costs than ceramics

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.