Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Introduction to ESD

Most of us have experienced a mild electric shock, such as the discomfort of being shocked when wearing shoes with rubber or plastic soles on a carpet and then touching a metal doorknob, which is uncomfortable but harmless.

However, in certain environments, such as hospitals, getting an electric shock can be a bit of a problem. Nurses touching medical equipment may have their equipment damaged or malfunction due to an electric shock. This phenomenon is called electrostatic discharge, or ESD.

In the example above, the electric shock was caused by the sole of a shoe. If the material used in the sole of the shoe is highly insulating, it will collect the electronic charge from the carpet, but will not release it. However, there is another solution, which is to use conductive materials for the soles of shoes or carpets, which can prevent the phenomenon of electrostatic discharge.

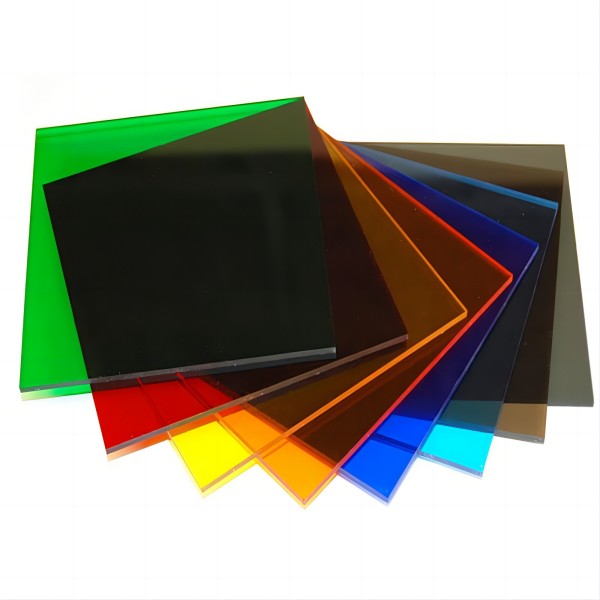

Plastic materials for anti-static mainly include the following:

Anti-static plexiglass sheet (anti-static acrylic sheet). This is a common anti-static plastic material with good transparency and anti-static properties.

Anti-static PVC plate (anti-static polyvinyl chloride plate). pvc is a common plastic material, by adding conductive agent or static inhibitor can realize anti-static effect.

Anti-static PC sheet (anti-static polycarbonate sheet) PC is a high-strength and high-transparency plastic material, can be added by adding conductive agents or static inhibitors to achieve anti-static effect.

Anti-static PET sheet (Polyethylene terephthalate).PET is a commonly used engineering plastic with good insulating and chemical resistance.Anti-static effect can be achieved by adding conductive agent or static inhibitor.

Anti-static nylon sheet (MC501CDR6). Nylon is a commonly used engineering plastics with good mechanical strength and chemical resistance. Anti-static effect can be achieved by adding conductive agent or static inhibitor.

Antistatic Polypropylene ( PP ). Polypropylene is a common plastic material, can be added by adding conductive agents or static inhibitors to achieve anti-static effect.

Anti-static polyethylene ( PE ). Polyethylene is also a common plastic material that can be antistatic by adding conductive agents or static inhibitors.

Antistatic Polyimide ( PI ). Polyimide is a high-performance engineering plastic with good high temperature and chemical resistance, and can be used to achieve anti-static effects by adding conductive agents or static inhibitors.

There are also anti-static Polystyrene (PS) and PC/ABS. These materials have a wide range of applications in the electronics, medical, packaging and other industries

Characteristics of anti-static plastic

Antistatic plastic is a kind of special engineering plastics with low surface resistivity and good antistatic performance. Its main characteristics are as follows:

1. good electrical resistance: the resistivity of anti-static plastic is between 10^6~10^9Ω/cm, which can effectively prevent the generation of static electricity.

2. Good chemical resistance: anti-static plastic can withstand the erosion of a variety of chemicals, such as acids, alkalis, oils and so on.

3. Good abrasion resistance: anti-static plastic has good abrasion resistance, widely used in mechanical equipment.

The application of anti-static plastic

1. Electronic components: anti-static plastic as a packaging material for electronic components can effectively prevent electrostatic interference. In the semiconductor, integrated circuits and other fields, the application of anti-static plastics is particularly widespread.

2. Medical devices: anti-static plastics have good biocompatibility and do not cause harm to the human body. Therefore, in the production of medical devices, anti-static plastics can be used to manufacture surgical instruments, handles, shells of medical instruments and so on.

3. explosion-proof equipment: because of the good anti-static properties of anti-static plastics, they can be used to make explosion-proof equipment shells and other parts to prevent sparks from triggering explosions.

4. automobile parts: in the production of electronic equipment, instruments, buttons, switches and other parts of the car, anti-static plastic can ensure the stability and reliability of electronic components.

5. electrical equipment: in the production of high-voltage electrical equipment, the application of anti-static plastics can effectively prevent electrostatic interference, to ensure the safety and reliability of electrical equipment.

Conclusion

Antistatic plastics have the characteristics of low surface resistivity, good chemical resistance, good abrasion resistance, etc., and are used in a wide range of applications, including electronic components, medical devices, explosion-proof equipment, automotive parts, electrical equipment and so on. With the continuous development of science and technology, the application fields of antistatic plastics will be further expanded.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.