Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

What is the purpose of FR4 machined parts?

FR4 fiberglass board, FR4 aka fiberglass board, FR4 reinforcement board, FR4 epoxy resin board, flame retardant insulation board, epoxy board, FR4 light board, FR4 epoxy glass cloth board, circuit board, drilling pad board.

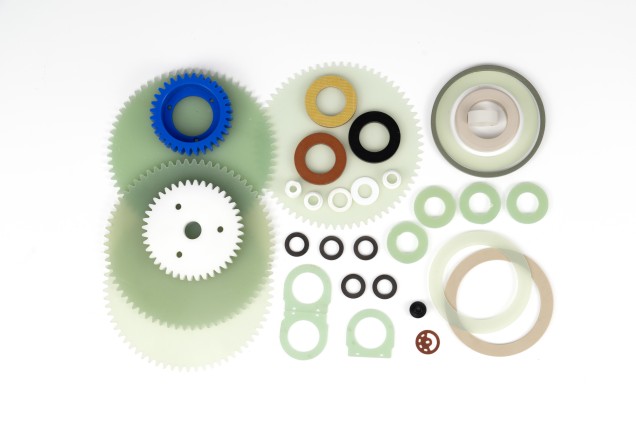

Fiberglass board alias, fiberglass insulation board, fiberglass board FR4, fiberglass synthetic board, synthesized by fiberglass material and high heat-resistant composite material, does not contain harmful asbestos components. It has high mechanical and dielectric properties, good heat and moisture resistance, and good processability. It is used for plastic molds, injection molds, machinery manufacturing, molding machines, drilling machines, injection molding machines, motors, PCB, ICT fixtures, table grinding pads.

The main technical characteristics and applications of white FR4 light board: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance exceeds the standard, suitable for application in high-performance electronic insulation requirements of the product, such as FPC reinforcement board, over tin furnace high temperature resistant board, carbon film sheet, precision touring wheel, PCB test frame, electrical and electronic equipment insulation board, insulation pads, transformer insulating parts, motor insulation parts, the Deflection coil terminal boards, electronic switch insulation boards, and so on.

Product processing methods

1. Drilling

This is a PCB circuit board factory common processing methods, whether it is PCB test fixtures, or PCB post-processing will go through & ldquo; drilling & rdquo;, the larger PCB factory usually set up their own drilling room, drilling room is usually closer to the fixtures, and drilling room of the work is not an easy job, but relatively free, usually drilling room consumables and equipment used in the drilling machine, drilling nozzles, glue particles, wood pads, aluminum pads, etc., drilling loss and pad loss is huge, many small companies usually supply a factory to get the drill nozzle and milling cutter to make a fortune. Usually, the consumables and equipment used in the drilling room are drilling machine, drilling nozzle, glue granule, wood mat board, aluminum mat board, etc. The loss of drilling nozzle and the loss of mat board are huge, and a lot of small companies usually supply a factory to get the drilling nozzle and milling cutter to make a big fortune;

Another common way of drilling and new up LED lampshade fixed insulating parts, LED as an energy-saving industry in recent years has received popularity, and LED by a large number of small lamps, this feature makes the insulating board applications again to broaden the field of application, usually the LED fixed insulating parts of the processing is drilling and then gong a circle can be processed in a relatively simple way, the market is huge, but the characteristics of the grade is not high, and Low profit;

2. Computerized gong

Computer gong is the name of Guangdong and Hong Kong, commonly known as CNC or CNC, there are also called machining centers, in fact, are a meaning, the computer gong is very powerful, which is divided into plane and beveled (or called curved surface), beveled category is relatively small, and the plane of the computer gong is very extensive, such as insulating gaskets, insulating rod, vernier wheels, and other small machining parts are used in the way of computer gong! Processing of epoxy board, computer gong zui big feature is flexible, fast, powerful, is currently also zui commonly used processing methods;

3. Slitting

This is the market zui common is also zui common processing methods, general stores have a cutting board machine cutting boards with, and this is usually more rough, the tolerance of the large can be controlled within 5mm, to say that scary, I've seen a lot of Dongguan to do epoxy board stores or companies, do probably more than 5 years of the company is actually still using the Angle Iron welded cutting machine cutting, Dongguan is known as the capital of the manufacturing, it does seem to be a great power. It seems to be a magical power, this way there is no technical content, but sometimes quite *, for example, sometimes the normal calculation of a sheet and a half is cut into 8 small sheets, there is a small waste, but those stores selling boards have a way to a board cut into 10 small sheets, if the volume is large, the profit will be very substantial;

4. Milling machine / lathe

This type of processing out of the product, usually parts and such products, because the milling machine and lathe was mostly used for hardware parts processing with, but ordinary milling machine and lathe processing speed is a big feature, so if you rely exclusively on this type of epoxy board processing methods, then the company's life expectancy will be greatly reduced, but to do fixtures, these two types of equipment *, that is to say, if the processing thickness of the thicker epoxy boards, then, if you are a good choice, the company's life expectancy will be greatly reduced. That is to say, if the processing thickness of the thicker epoxy plate, milling machine and lathe is

5. Precision engraving machine

Computerized engraving machine by the computer, engraving machine controller and engraving machine host three parts. Its working principle is: through the computer configuration of the carving software for design and layout, and by the computer to the design and layout of the information automatically transmitted to the controller of the engraving machine, and then by the controller to convert this information into a stepper motor or servo motor can be driven with the power of the signals (pulse string), control of the engraving machine host to generate the X, Y, Z-axis of the engraving of the three-axis knife path base path. At the same time, the high-speed rotary engraving head on the engraving machine, through the processing of materials configured according to the cutting tool, fixed in the host table for the processing of materials cutting, can be carved in the computer designed in a variety of plane or three-dimensional relief graphics and text, to achieve automated operation of the engraving.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.