Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Plastics in Detail

Acetal = Polyoxymethylene (POM) = Polyacetal = Polyformaldehyde, Race Steel

Key properties: high mechanical strength and stiffness, low coefficient of friction, good wear resistance, natural lubrication, machinability, low moisture absorption, chemical resistance.

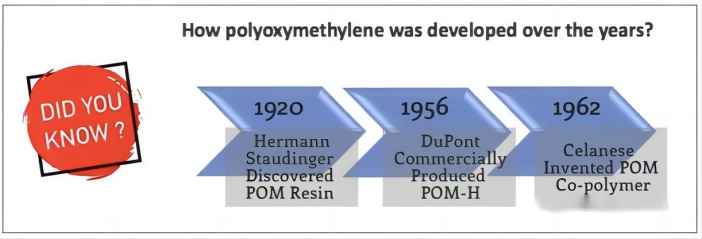

History of Race Steel: Herman discovered Race Steel in 1920, DuPont commercially produced the acetal homopolymer POM-H in 1956, and Celanese invented the polyformaldehyde copolymer POM-C in 1962.

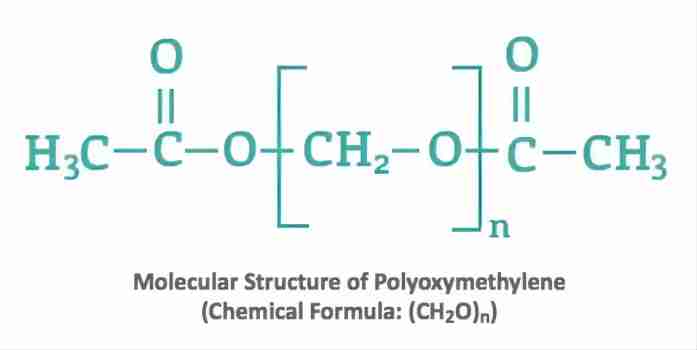

Acetal is acetal, also known as polyacetal, also known chemically as polyformaldehyde, i.e. Polyoxymethylene (POM), is a formaldehyde-based semi-crystalline engineering thermoplastic.

So many times, Acetal is abbreviated to POM in expression.

POM chemical structure

Acetal is commonly known as race steel and is commonly available in black and white, Acetal-Black and Acetal-White.

Acetal is processed in standard billet shapes and then extruded into sheets, rods and tubes.

Acetal has high mechanical strength and stiffness, good sliding characteristics (low coefficient of friction), and excellent wear resistance.

Because acetal absorbs little water, it has excellent dimensional stability and is an excellent choice for complex shapes and precision machined parts. Also because of low water absorption, raceway bearings outperform nylon by a factor of 4 in high humidity or submerged applications.

Due to the chemical structure of racemic steel, it is unstable in acidic conditions and at high temperatures, where the polymer degrades. As a result, POM is often copolymerized with cyclic ethers such as ethylene oxide or diepoxide to change the chemical structure and thereby improve stability.

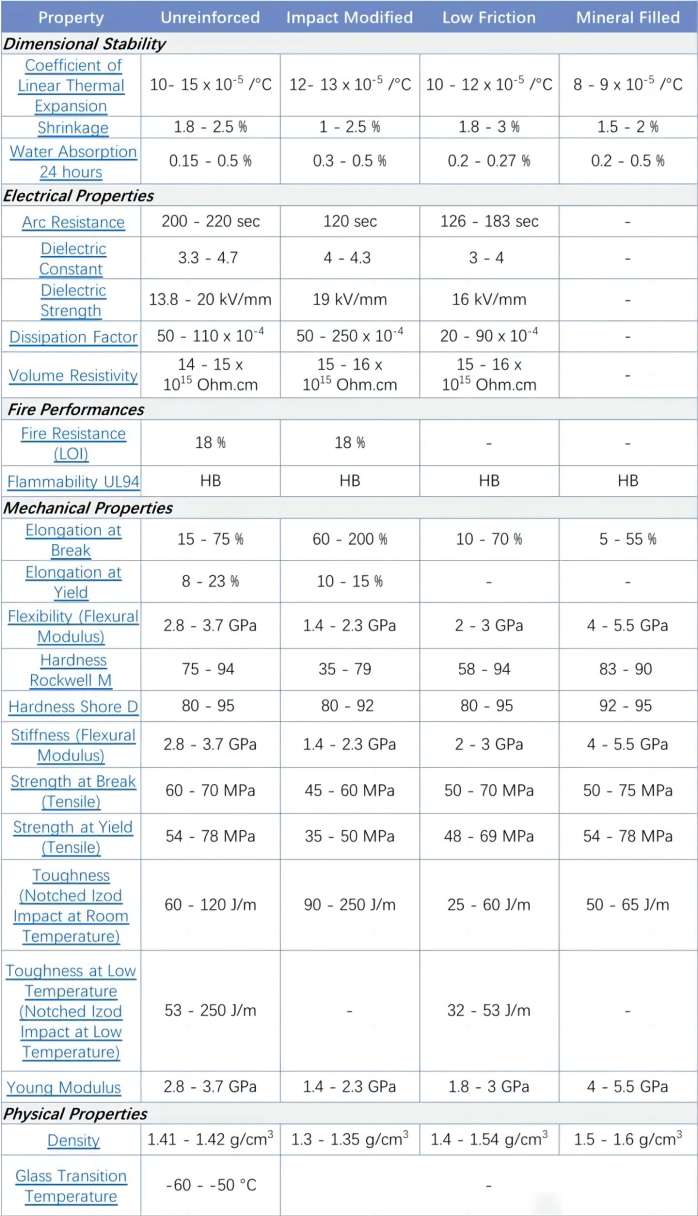

Various types of raceway properties: unreinforced, impact-modified, low-friction, mineral-filled types, and more. Cycloidal steel reinforced with glass fibers, carbon fibers or glass spheres for high tensile strength or stiffness. Blending CycloSteel with rubber, TPU and other polymers results in blends with higher impact strength. Adding graphite, PTFE, mineral fillers, etc. enhances wear resistance and lubrication.

Additionally, due to the large amount of oxygen in the molecule, it is difficult to impart flame retardancy and has a continuous operating temperature range of about -40°C to 120°C.

Example applications include: gears, bearing bushings, rollers and slides, housing parts, nuts, fan wheels, pump parts, valve bodies. Electrically insulated parts. Components in contact with water, scratch-resistant high-gloss exposed parts. Various components for the food, pharmaceutical and drinking water industries, as well as for medical technology.

POM-H, POM-C

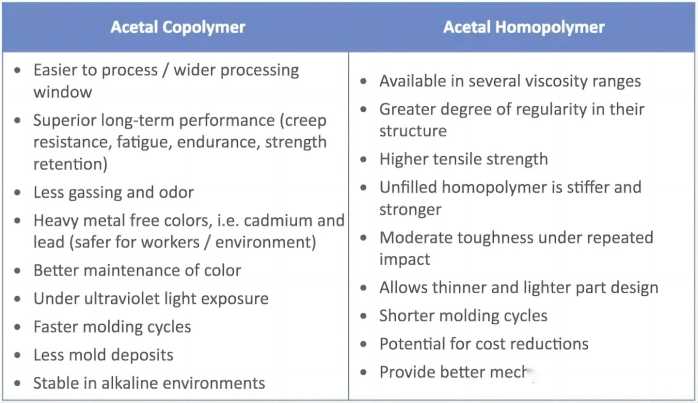

There are two variants of POM, Acetal Homopolymer POM-H and Acetal Copolymer POM-C. They have the same impact properties.

POM-H = Acetal Homopolymer, POM-C = Acetal Copolymer.

Acetal Homopolymer POM-H and Acetal Copolymer POM-C Properties

POM-H is produced by an anionic polymerization reaction of formaldehyde, which is well crystallized, resulting in high stiffness and strength; POM-H is 10-15% stronger than POM-C.

However, POM-C has higher chemical resistance and lower melting point than POM-H. Also, it has high processability compared to POM-H. As a result, POM-C has become the most widely used type of POM, accounting for 75% of total POM sales.

POM-H is best suited for applications requiring good abrasion resistance and a low coefficient of friction, and POM-C is well suited for applications requiring a low coefficient of friction.

To summarize, POM-H and POM-C have the following differences.

Hardness and stiffness:

POM-H: POM-H is stiffer.

POM-C: POM-C is not as stiff as POM-H.

Machinability:

POM-H: Lower machinability.

POM-C: High machinability.

Melting point:

POM-H: melting point of 172-184 ° C.

POM-C: Melting point of 160-175°C.

Modulus of elasticity (MPa) (water content of 0.2% in tension):

POM-H: Modulus of elasticity 4623.

POM-C: Modulus of elasticity 3105.

Widely Application:

POM-H: POM-H accounts for about 25% of total POM sales.

POM-C: POM-C accounts for approximately 75% of total POM sales.

Areas of application:

POM-H: Bearings, gears, conveyor belt links, seat belts.

POM-C: Electric kettles, components with snap fits, chemical pumps, telephone keypads, etc.

FAQ:

What is the difference between POM and POM-C?

POM vs. POM-C: Understanding the Differences in Engineering ...

POM-C, also referred to as acetal copolymer, is produced using a copolymerization process. By introducing a comonomer during the polymerization, the material exhibits enhanced toughness, impact resistance, and better chemical resistance compared to POM.

What is the difference between POM copolymer and homopolymer?

Polyacetal (POM) | When to Select Homopolymer or Copolymer?

Because of the higher crystallinity, homopolymer has a higher heat distortion temperature but copolymer grades have higher continuous use temperatures because of better long term stability.

What is the difference between acetal and pom-C?

In comparison to acetal homopolymer, POM-C provides enhanced resistance to chemicals and offers lower co-efficient of friction, but it is less dense than POM-H and is therefore not as hard wearing. Acetal copolymer also has a lower operating temperature and melting point than acetal homopolymer.

What is the difference between Delrin and Pom C?

Delrin has a hardness of 86 Shore D while POM copolymers have a hardness of 85 Shore D. Therefore, Delrin will be more resistant to impacts and abrasion. Also, it will have a lower coefficient of friction. Therefore, it will be able to slide over other parts easily.

What plastic is stronger than Delrin?

Delrin vs Nylon: Comparing Two of the Top Plastic Polymers ...

While both materials are strong and durable, nylon has a higher tensile strength of 12,000 psi than Delrin with 10,000 psi. However, both materials are versatile and have high impact and wear resistance.

What material is better than Delrin?

Nylon is the best material to work with if you are looking to use 3D printing capabilities, and it also can be used in higher temperature situations than Delrin.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.