Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

With the rapid development of high technology, people understand more and more in-depth durostone, from the company created the initial to the current durostone applications have become more and more extensive, from the beginning of the application of durostone is only used for wave soldering; reflow soldering; jig; tray; jig; tin paste printing and other fields, to the present synthetic stone has become a machine; equipment; parts; toasters and other food processing machinery industry; aviation warships and other Indispensable products.

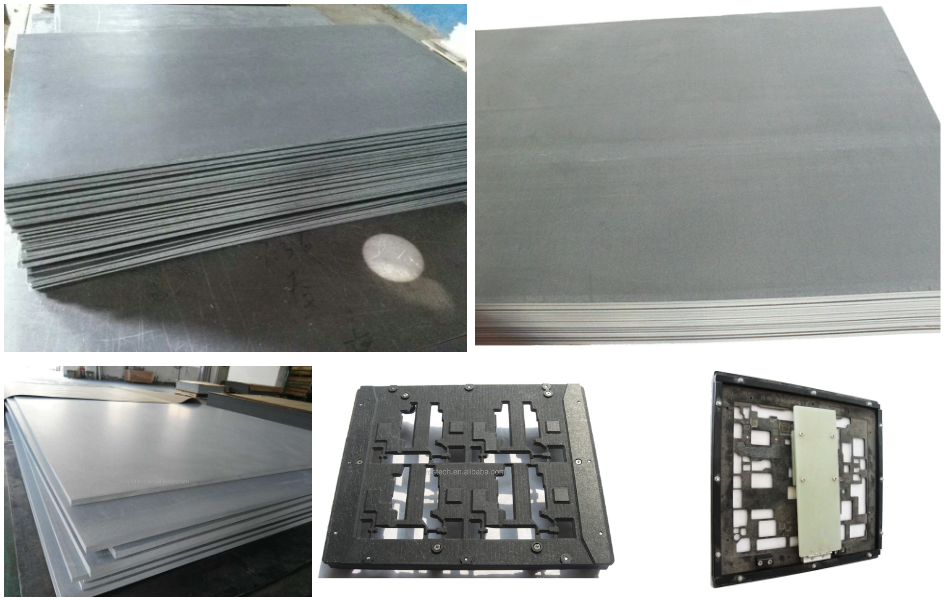

Durostone is a kind of composite nanomaterials made of short-fiber glass mat and high-strength epoxy resin, with low thermal conductivity, resistance, high temperature resistance, anti-static, chemical corrosion resistance and other characteristics. Durostone carbon fiber plate is widely used in electronics, aviation, warships and ships and other fields. In electronic manufacturing, welding use and other protective materials, durostone carbon fiber plate material with easy processing, high strength, for electronic manufacturing wave soldering; reflow soldering provides a long-lasting, durable, high temperature resistance, anti-static PCB board carrier material. The degree of temperature resistance of durostone can withstand up to 425 degrees! And in the high-temperature working environment in continuous use can also maintain good mechanical strength. Durostone carbon fiber board can be fully adapted to 360 degrees wave soldering, reflow soldering high temperature process and production needs. Durostone can last up to 20,000 cycles in continuous use in high-temperature production lines.

Characteristics of Durostone

A: Synthesized stone (high temperature nanocomposites) maintains excellent physical properties at elevated temperatures;

B: Synthesized stone can maintain dimensional stability and flatness after repeated substrate mounting process:

C: The low thermal conductivity of Synthesized Stone (High Temperature Nanocomposites) ensures heat distribution on the substrate;

D: The characteristics of the synthesized stone (high temperature nanocomposites), the substrate mounting jig can do precision processing;

E: Synthesized stone (high-temperature nanocomposites) in the high-strength resin can effectively block the characteristics of the flux, to prevent the generation of tin tip.

Application of Durostone: range of tin paste printing; SMT placement; reflow soldering; wave soldering; conformal coating; machinery; equipment; parts; temperature insulation, and so on.

The role of Durostone in PCB assembly process:

(1) Avoid contamination due to human touch;

(2) Reduce scrap;

(3) Prevent PCB bowing;

(4) Standardization of production line width;

(5) Use of multi-functional fixtures to increase production capacity;

(6) Cover the bottom of the SMT components, so that through the standard reflow soldering equipment to do localized soldering;

The role of Durostone in wave soldering

In the environment of gradually increasing temperature, the synthetic stone can continue to maintain its physical properties, so that the synthetic stone can be in the wave soldering process, to achieve a high standard of results, and the synthetic stone will not have deformation of the situation. The composite stone will not cause delamination, blistering, deformation, etc., even if it is subjected to a short period of time at 425 degrees Celsius and continues to be subjected to the harsh environment of 380 degrees Celsius operating temperature.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.