Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

FR4 Epoxy Tourbillon Wheel for Polishing and Grinding

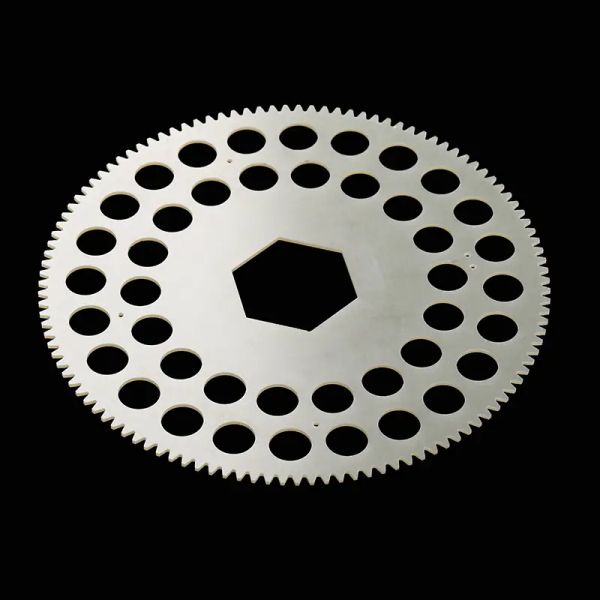

FR4 Epoxy Plate Tourbillon Wheel for Polishing and Grinding Polishing refers to the treatment of an object using mechanical or chemical reactions to make its otherwise rough surface smooth and flat. Some products, such as mirrors, gemstones, cell phone screens, silicon wafers, etc. need to be polished before official use. Star wheel is commonly used polishing instruments, according to the different materials can be divided into blue steel and epoxy plate two kinds, blue steel wear resistance is good, but the manufacturing process is complex, the price is very expensive, epoxy star wheel is not only good performance, the price is also cheap, is very popular. FR4 and epoxy plate in the cost-effective and outstanding a model, this article will take you to understand the FR4 epoxy plate star wheel.

What are the features of the Star Cruiser?

High-quality fiberglass fiberboard (FR-4) material properties: high temperature resistance of 180 ~ 200 ℃, high mechanical and dielectric properties, high temperature, shade and moisture resistance, smooth surface, good workability.

The finished product has very high processing precision, which can be controlled within 0.02mm, and the cut surface is very smooth and clean, there will not be any burrs, and even the traces of processing cannot be seen.

Stable electrical insulation properties, smooth surface, no pits, standard thickness tolerance, suitable for high-performance electronic insulation requirements of products, such as FPC reinforced boards, PCB drilling spacers, fiberglass interfaces, potentiometer carbon film printed fiberglass fiberboard, precision star wheels (used in lenses, silicon wafers, etc.).

Some of the uses of a cruise ship

Material used: high quality fiberglass board (FR-4) material properties:, high temperature resistance 180-200 ℃, with high mechanical properties and dielectric properties, good heat resistance and moisture resistance, smooth surface, and has good machinability.

Size: can be customized.

Material color: white, yellow, black, aqua green.

Suitable for: all kinds of products that need to be ground and polished, the application is very wide. Such as: cell phone glass (cell phone touch screen) hard disk ......

Composite Tourbillon wheel in the field of double-sided grinding has begun to batch use, here I give you an explanation of the so-called composite tourbillon wheel is.

The so-called composite vernier wheel both the middle epoxy resin material, outside the gear steel ring. Combined use. This practice in the field of double-sided grinding has been heterodox. There are mainly the following disadvantages:

1, Grinding stability is not high. Mainly the gear ring is easy to twist and deform, resulting in disk.

2, The combination of human negligence led to disc.

Since it is easy to turn over, why are there still people willing to use it?

We know that in the ultra-thin parts grinding and polishing, due to the thin wheel, plastic materials have been difficult to handle, but the metal wheel is easy to bite the products. Therefore, the composite class of the planetary wheel still has its market space.

After 3 years of development, the composite touring wheel has begun to mature. Our company has made continuous improvement to the composite touring wheel.

1, Gear ring from ordinary steel to high-strength stainless steel

2, Gear ring structure from the original structure with hooks to the multilateral structure.

3, Epoxy plate changed to alkali-free glass fiber epoxy plate

In this way, with the manufacturers in the double-sided grinding process adjustment, basically did not find the phenomenon of flopping. Welcome manufacturers to improve your experience, Sheng Keda Precision has been committed to the field of double-sided grinding fixtures, hoping to make progress together.

When the upper and lower grinding discs of the double-sided grinding machine work for a period of time, the grinding disc will be damaged to a certain extent, in order to ensure that the grinding discs of the surface accuracy of the processing capacity, our double-sided grinding machine can be added to the upper and lower grinding discs can be corrected to the surface of the machine, it became the large double-sided grinding machine. The purpose of the four stages of pressure is to apply different weights of pressure to different workpieces, so as to achieve the ideal surface accuracy effect.

The structural features of the large double-sided grinder are as follows:

1. Series of large-scale double-sided grinding machine runs with four motor drives, which can be given to the upper grinding disk, lower grinding disk, tooth ring, sun wheel separate speed regulation, so that the grinding to achieve a more ideal speed ratio, its sun wheel relative to the other three speed ratio can be made stepless speed regulation, so that the cruise wheel

The speed ratio of the sun wheel to the other three speeds can be adjusted steplessly, so that the traveler wheel can realize positive and negative rotation, which meets the needs of different grinding and disk repairing processes.

2. The series of large double-sided grinding machine is the lower grinding disk lifting mode, the lower grinding disk height position can be in the total range of travel stay self-locking in order to meet the need to change the high and low position of the cruise wheel engagement.

3. The series of grinding machine adopts four stages of pressure, i.e. light pressure, medium pressure, heavy pressure, and the operation process of repairing and researching.

4. Series of large double-sided grinding machine adopts PLC program control system, touch screen operation panel, motor adopts frequency conversion speed control, motor speed and running time can be directly input into the touch screen.

5. According to the user requirements to increase the grating thickness control system, the thickness tolerance of the processed products can be controlled within the range of ± 0.002mm; flatness tolerance can be controlled within the range of ± 0.001mm.

Large double-sided grinding machine structure is solid, excellent performance, but also has a self-repair disk function, is the ideal equipment for processing double-sided workpiece.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.