Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

G10 epoxy board of these three processing methods, are you clear?

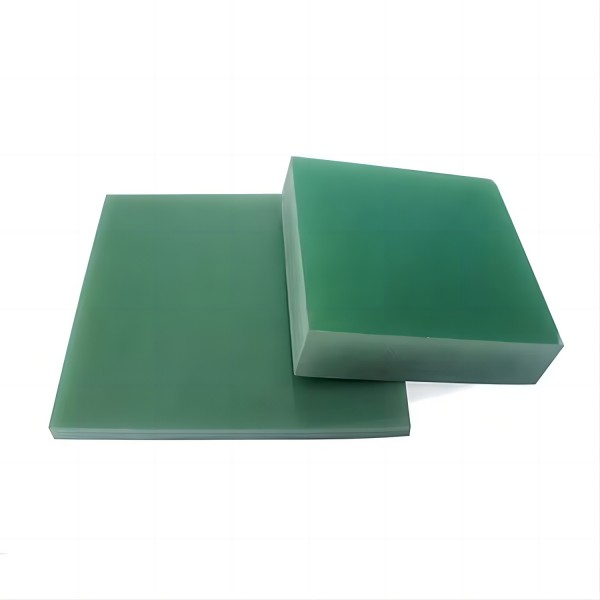

G10 epoxy board is made of glass fiber cloth bonded with epoxy resin with temperature and pressure to produce a successful, 3240 in a medium temperature environment with high mechanical properties, in high humidity can also maintain high electrical properties, so it can be used in machinery, electrical appliances and electronics with high insulation structure parts. It has good dielectric properties, heat resistance and moisture resistance.

We all know that it is a type of epoxy board that we often say, its temperature resistance grade is F class, that is, it can withstand 155 degrees of high temperature, has good mechanical properties and dielectric properties, suitable for mechanical manufacturing insulation parts, transformer skeleton and so on. It is processed by glass cloth and epoxy resin after lamination and other processes, and is more common .

Epoxy board has good high temperature resistance, this point in the insulation material industry is a must. So have you ever wondered what are the processing methods of G10 epoxy board? This is the topic I want to share with you.

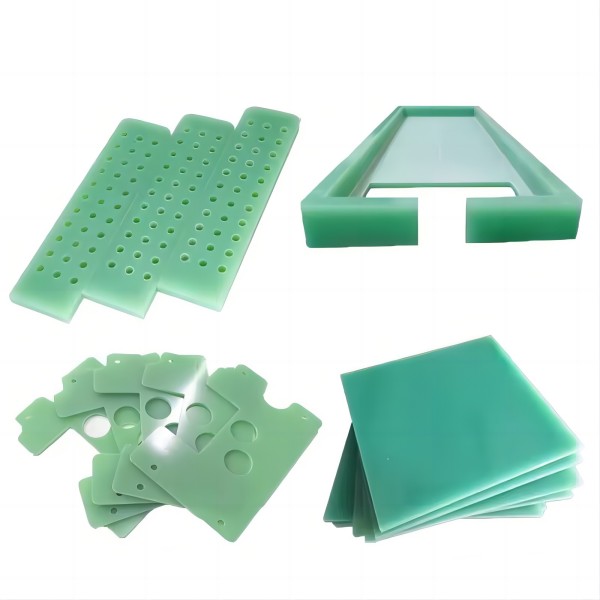

Processing methods:

1.Computerized gong

Computer gong is commonly known as CNC or CNC, also known as machining centers, in fact, are a meaning, the function of the computer gong is more good, which is divided into plane and beveled (or called curved surface), beveled category is relatively small, and the plane of the computer gong on a wider range of insulating gaskets, insulating rods, and other small machining parts are processed using the computer gong, computer gong is a larger feature is flexible, fast, powerful, and is the largest insulating material industry, the computer gong is the most powerful way to process the insulating material. The greater characteristics of computerized gong is flexible, fast, powerful, is currently the commonly used processing methods.

2.Drilling

This is a common processing method, whether it is testing fixtures, or post-processing will go through the "drilling", the larger manufacturers usually set up their own drilling room, drilling room is usually more closely linked with the fixtures, and drilling room work is not an easy job, but relatively free, usually drilling room with the supplies and equipment is the drilling machine, drilling nozzles, adhesive particles, wood, aluminum, etc.. wood pads, aluminum pads and so on.

3.Slitting

This is a common processing method in the market, general stores have a cutting machine to cut the boards, and this is usually relatively rough, processing G10 epoxy boards when the tolerance can be controlled within 5mm.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.