Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

ICT test fixtures are used to check the open and short circuit conditions of individual components and circuit networks online.

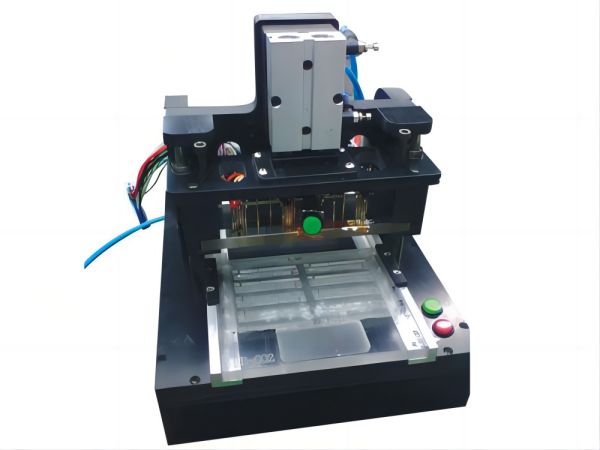

ICT test fixture is the abbreviation of Integrated Circuit Tester, which is an on-line inspection and test fixture. It is a standard test equipment for testing the electrical properties and electrical connections of on-line components to check manufacturing defects and defective components.

ICT test fixtures can be analog device function and digital device logic function test, high fault coverage, for each kind of veneer need to make a special needle bed, this needle bed in industrial production is called it ICT test fixtures.

Characteristics

ICT test jig with single-sided and double-sided, universal ceiling to facilitate the exchange of machine types, the use of adjustable Perrin seat, easy to maintain, the use of acrylic & bakelite & FR-4 material (or specified), direct gerber file processing to generate drilling files, to ensure the accuracy of drilling. The test program is automatically generated, avoiding the possibility of manual input errors Applicable to tri, jet, newsys, okano, tescon, takaya, gwposhell, src, concord, PTI816 and other ICT models. Center distance between two measured points or measured points and pre-drilled holes shall not be less than 0.050" (1.27mm). A distance greater than 0.100" (2.54mm) is preferred, followed by 0.075" (1.905mm). The test points of the fixture should be distributed as evenly as possible to ensure that the board does not change shape after being pressed on to avoid damage to the product.

Functions

ICT test fixtures are capable of checking the electrical performance of in-line components on manufactured boards and the connection of circuit networks. It can quantitatively measure resistors, capacitors, inductors, crystals and other devices, and functionally test diodes, transistors, photocouplers, transformers, relays, operational amplifiers, power supply modules, etc. It also functionally tests small and medium-sized integrated circuits, such as all the 74-series, Memory-type, commonly used driver-type, switching-type and other ICs.

ICT test fixtures detect manufacturing process defects and defective components by directly testing the electrical performance of in-line devices. Components can be checked for over-value, failure or damage, and Memory can be checked for program errors. For the process category can be found such as solder short circuit, component insertion error, insertion of the reverse, leakage, pin warping, false soldering, PCB short circuit, broken wires and other faults. Test faults are directly positioned in the specific components, device pins, network points, fault location is accurate. Fault repair does not require more specialized knowledge. The use of program-controlled automated testing, simple operation, fast and rapid testing, single-board test time is generally a few seconds to tens of seconds.

On-line test is usually the first test process in production, which can timely respond to the manufacturing situation, and is conducive to process improvement and enhancement. ICT test fixtures tested faulty boards, due to accurate fault localization, easy to repair, and can significantly improve production efficiency and reduce maintenance costs. Because of its specific test items, it is one of the important test means for modernized mass production quality assurance.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.