Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The role of screws is mainly to connect two workpieces together and act as a fastener. Screws are used in general equipment, such as cell phones, computers, cars, bicycles, all kinds of machine tools, equipment, and almost all machines. Screws have important tasks in industry, as long as there is industry on earth, the function of screws will always be important. Screws have been a common invention in people's productive lives for thousands of years and are the first major invention of mankind according to the field of application.

Screws in the development of the past few years, but also encountered a variety of serious challenges, such as iron screws if they are wet, will be very likely to rust. The high-performance polyether ether ketone (PEEK) material, with its unique properties and stable performance in all kinds of harsh environments, has become one of the more ideal materials in the screw world.

PEEK belongs to a semi-crystalline thermoplastic and high-purity polymers, with excellent mechanical strength and chemical resistance at high temperatures, PEEK screws for PTFE fluoropolymer to provide high-strength alternatives.

PEEK screws with PEEK as raw material, injection molding through the mold, thread precision of 6g, due to the excellent performance of PEEK material, PEEK screws compared to traditional nylon, PC, PP and other screws have the following characteristics:

1, Corrosion resistance, thanks to the excellent chemical resistance of PEEK materials, PEEK screws can withstand most of the corrosive solvents, corrosion resistance second only to fluoroplastics;

2, High temperature, PEEK screws long-term temperature 220 degrees;

3, High strength, excellent mechanical strength, M6 bolts can carry a load of more than 150KG;

4, Low temperature resistance, can be used in -50 ℃ environment;

5, Radiation resistance, can withstand ultraviolet light, steam, high dose of gamma rays;

6, Excellent resistance to thermal degradation, able to resist chemical decomposition caused by heat.

7, Good chemical resistance, chemical resistance to many oils, alcohols, solvents and organics as well as harsh acids and bases at low concentrations and low temperatures.

8, Hydrolysis resistance provides PEEK at high temperatures and high pressures when continuously exposed to water or steam to maintain all physical properties, as well as providing very low moisture absorption.

9, Excellent creep resistance allows PEEK screws to withstand high stresses over a long service life.

10, Good abrasion and wear resistance; maintain electrical properties over a wide range of frequencies and temperatures; radiation resistance allows PEEK to be used for high doses of ionizing radiation or repeated sterilization through high doses of ionizing radiation.

PEEK screws compared to metal screws, although the mechanical strength is weaker, but in terms of insulation, weight reduction and other aspects of the metal screws can not be compared.

PEEK screws of the development trend of the history of time is only a few years, but because it has a prominent temperature resistance, chemical corrosion resistance, and its high toughness, easy to process performance, prompting it has been in China's industry, chemical industry, electrical and electronic, machinery and equipment dashboards, automotive industry and aerospace industry has gained widespread use.

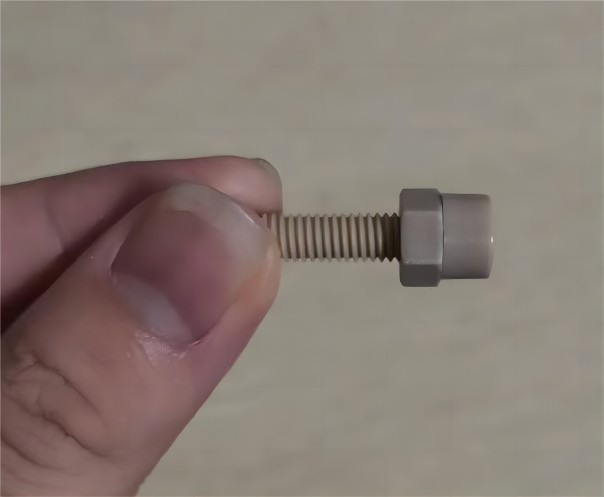

HONY plastic produces PEEK screws with the following specifications:

One-piece round head PEEK screws

One Hexagon Socket Head PEEK Screws

Hexagon socket head PEEK screws

Phillips round head PEEK screws

Hexagon socket head PEEK screws

Flat head PEEK screws

PEEK nuts

Customized PEEK screws, nuts, nuts, screws, bolts, etc. of various specifications.

Precautions for using PEEK screws/bolts

1. Plastic bolts are standardized by ISO specifications. However, the manufacturing process of plastic and metal bolts is different, so some parts are not fully applicable.

2.Mechanical properties data is for reference only, may vary depending on the use of different working conditions.

3.Acid and alkali resistance may vary depending on the conditions of use. It is necessary to realize the test under the actual use condition.

4.The color of small bolts and nuts may vary slightly due to different production batches.

PEEK screws/nuts

1.Product name: PEEK screws/nuts;

2.Product material: pure PEEK, other modified materials are also available;

3.Product color::natural color, black and others;

4.Product specification: please see the specification table below;

5.Production process: injection molding one time (non-standard products machining);

6.Quality standard: ISO9001, SGS, FDA, ROHS;

PEEK Properties Data Sheet

| Item | Test Standards | Conditional | Unit | Data |

| Color | | | | Natural |

| Density | GB/T 1033-1 | | g/cm3 | 1.3 |

| Tensile strength | GB/T 1040 | 23℃ | MPa | 100 |

| Elongation at break | GB/T 1040 | 23℃ | % | 34 |

| Flexural strength | GB/T 9341 | 23℃ | MPa | 163 |

| Compression strength | GB/T 1041 | 23℃ | MPa | 118 |

| Lzod impact strength | GB/T 1043 | Notchless | KJ/m2 | NB |

Ultimate Torque Data Sheet for PEEK Screws

| Screw specifications | Maximum torque N.m |

| M4 | 1.13 |

| M5 | 1.6 |

| M6 | 2.08 |

| M8 | 4.8 |

| M10 | 11.2 |

| M12 | 18 |

| M16 | 38.9 |

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.