Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PEEK tubing, what is PEEK tubing?

In order to meet the market demand, HONY Plastic's PEEK tubing to meet the application of different occasions has been mass-produced with high efficiency and good value for money. It can be used to manufacture all kinds of industrial piping, instrument piping, valve piping, pipe fittings and so on.

HONYPLAS® PEEK tubes include:

Red PEEK tubes (colours can be customised)

PEEK continuous extrusion pipe

Thin wall PEEK tubes

Large diameter PEEK tubing

Black PEEK moulded tubes

Support zero-cut PEEK tube

PEEK tubing is highly resistant to thermal degradation and attack by organic and aqueous media. It resists creep and maintains dimensional stability at high temperatures and pressures, making it ideal for use in sealing applications.

PEEK materials can be used continuously at temperatures up to 260°C, maintaining wear resistance and mechanical strength.

PEEK is an ideal high performance material for harsh environments such as high temperatures, wet processes and heavy loads. It combines excellent abrasion, chemical and moisture resistance with very high strength, dimensional stability and stiffness.PEEK can be continuously exposed to hot water or steam without distortion, corrosion or wear.

Properties of PEEK tubing

Excellent abrasion resistance and dimensional stability for continuous use at 260°C

Excellent resistance to chemicals, steam and hydrolysis

Very low moisture absorption

Very high thermal stability

Excellent bending and torsional strength

Abrasion resistance

Good dielectric properties

Good resistance to radiation

Areas of application for PEEK materials

Chemical technology

Mechanical industry

Energy industry

Electronics

Food Technology

Oil and Gas Industry

Aircraft and Space Technology

Automotive

Semiconductor technology

Vacuum technology

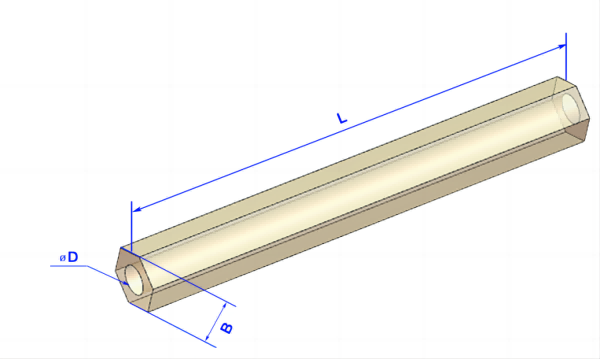

What is PEEK Hexagonal Extruded Tubing?

PEEK male hexagonal tube produced by continuous extrusion process solves the technical problems of limited height of products in moulding process and easy to produce internal shrinkage holes in injection moulding process, and at the same time reduces the material loss and lowers the machining cost. It can be used to process PEEK isolation column, PEEK hexagonal nut (machining), PEEK hand tight joints, PEEK hexagonal tee and other products with external hexagon.

Advantages of machined PEEK hexagon nuts compared with injection moulded nuts

◆ There is no glue point in the appearance of machined PEEK hexagon nuts;

◆ There is no parting line on the appearance of machined PEEK hexagonal nuts, the appearance is more beautiful;

◆ No burr on the appearance of machined PEEK hexagon nuts;

◆ Machined PEEK hexagon nuts have better mechanical properties.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.