Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

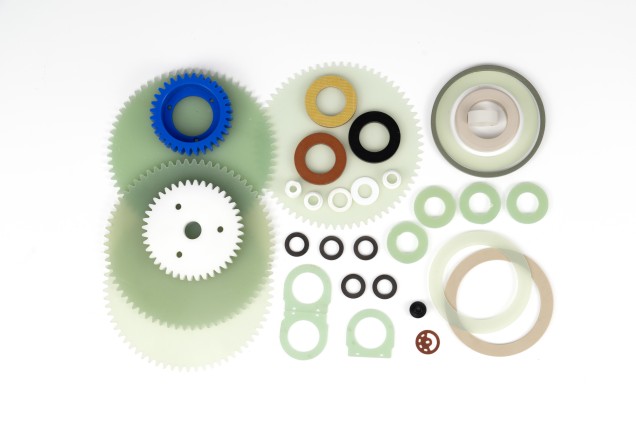

Epoxy board processing and processing other insulating panels are the same: turning, milling, cutting, carving, grinding. The process of epoxy board processing and the use of different processing equipment.

In the process of epoxy processing should pay attention to what details:

1. The process of processing will produce clear chips and cooling problems, available compressed air blowing flow adjusted a little smaller, to just blow the net chips on the line.

2. Epoxy plate processing will produce a lot of dust, you can also choose to operate with water, to choose the decorative industrial vacuum cleaner.

3. The process of processing, there will be too high a temperature. We have to control the temperature at the right time. The base material of epoxy board is epoxy resin glue, and the melting point of epoxy resin glue is about 155 degrees. Above this temperature, the board will appear softening phenomenon.

4. Choose the right epoxy board, if the pressure requirement is not high, you can choose general 3240 epoxy board. Used for general insulation works. If the voltage requirement is very high, you can choose FR4 epoxy board.

Precautions during the processing of epoxy plates

Epoxy sheet is a commonly used engineering plastic material with excellent mechanical, electrical and chemical properties. During the processing of epoxy sheet, the following matters need to be noted to ensure the processing quality and operation safety.

1. Select the appropriate processing process: According to the desired processing objectives and requirements, select the appropriate processing process, such as cutting, drilling, grinding, etc.. Different processing processes have different requirements on the characteristics and applications of epoxy boards, which need to be selected according to the actual situation.

2. Maintain a good operating environment: It is very important to maintain a good operating environment during the processing. Ensure that the operating area is well ventilated and away from flammable, explosive and other hazardous materials. At the same time, operators should wear appropriate protective equipment, such as gloves, goggles, etc., to protect their own safety.

3. Use appropriate processing tools: Selecting the appropriate processing tools is the key to ensure the quality of processing. Use reliable quality, suitable for processing tools, such as high-speed drills, saw blades, grinding wheels and so on. Pay attention to keep the sharpness of the tools, and regularly check and replace damaged or badly worn tools.

4. Control the processing temperature: In the process of processing, control the processing temperature is very important. Excessive temperature may cause the material to melt, deform or undergo chemical reaction, thus affecting the machining quality. Therefore, it is necessary to control the appropriate processing temperature and take suitable cooling measures during the machining process to ensure the stability and quality of the machining process.

5. Prevent the generation of static electricity: epoxy boards are prone to static electricity, the accumulation of static electricity may cause interference in the processing or even damage to the material. Therefore, in the processing process, corresponding anti-static measures should be taken, such as the use of tools with anti-static devices, wear anti-static clothing, etc., in order to effectively prevent the generation and accumulation of static electricity.

6. Regular cleaning and maintenance of equipment: Regular cleaning and maintenance of processing equipment is the key to ensure processing quality and equipment life. Clean the chips and dirt on the equipment in time to keep the equipment in good condition. At the same time, regularly check and maintain the various components of the equipment, such as lubrication system, transmission device, etc., to ensure its normal operation and safe use.

7. Follow suppliers' recommendations: Different suppliers may provide different processing recommendations and parameters. During processing, the processing parameters should be reasonably adjusted according to the characteristics of the specific material and the supplier's suggestions, and the supplier's technical support and consulting services should be fully utilized.

To summarize, when processing, you need to pay attention to selecting the appropriate processing technology, maintaining a good operating environment, using appropriate processing tools, controlling the processing temperature, preventing the generation of static electricity, regular cleaning and maintenance of equipment, and follow the supplier's recommendations. By observing these precautions, the quality and efficiency of epoxy board processing can be improved while ensuring the safety of operators.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.