Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

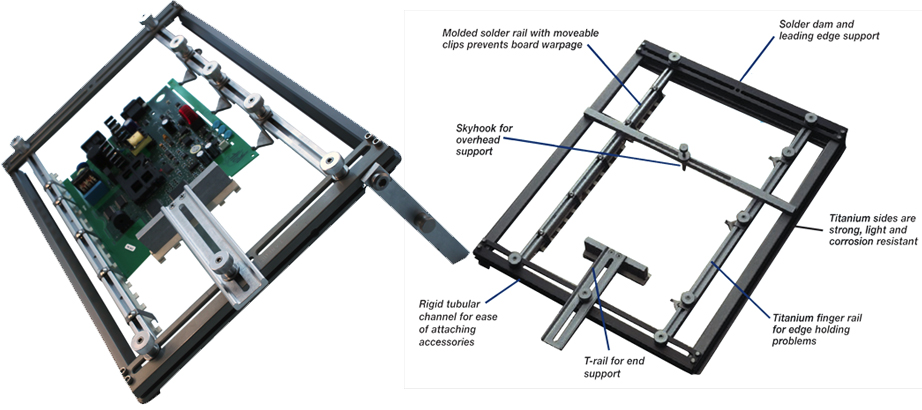

Wave Soldering Fixture from Hony Plastic

With the continuous development of the electronic field, the requirements for products are getting higher and higher, the functions of the products are becoming more and more powerful, the size is getting smaller and smaller, the design of the PCB is becoming more and more complicated, and the processing technology is becoming more and more complicated. The glue process is gradually replaced by the solder paste process, and the wave soldering fixture plays a big role here, which can solve the conflict between the solder paste process and wave soldering, and improve product quality. At the same time, higher requirements are put forward for wave soldering fixtures. The high temperature resistance of the material is better, the processing precision is higher, and the tinning effect is better.

Product name: Synthetic stone tin stove jig;

Scope of application: wave soldering in PCB manufacturing process;

Main material: synthetic stone (Rochling, Isola);

Product functions:

1. Support thin PCB board or flexible circuit board through furnace;

2. It is used for the furnace of irregular PCB boards;

3. Keep the PCB board from deformation under high temperature;

4. It is used for multiple PCB boards to pass through the furnace at the same time to improve the production efficiency of the equipment;

5. Design the universal wave soldering fixture according to the actual situation to reduce the production cost;

Product features:

1. High precision: high-precision CNC processing;

2. Anti-static: synthetic stone material has excellent anti-static performance;

3. Invariance: the openings are carefully designed to maintain the excellent mechanical properties of the material, and maintain the invariance of the PCB board at high temperatures;

4. High efficiency: multiple PCB boards can be placed on one furnace passing fixture to pass the furnace at the same time, improving the efficiency of the equipment;

5. Long life: 20,000 times long life, very cost-effective;

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.