Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:TECASINT

Min. Order:1 Kilogram

Model No:TECASINT 1061

Transportation:Ocean,Land,Air,Express

Packaging:Export package

TECASINT 1061 black POLYIMIDE with 15% graphite and 10% PTFE is Based on TECASINT 1011 material, TECASINT 1061 material was obtained by adding 15% graphite and 10% PTFE development. Its properties include very low static friction and a low...

Brand:HONYPLAS

Min. Order:1 Kilogram

Model No:Vespel Sheet Rod

Transportation:Ocean,Land,Air,Express

HONYPLAS®Polyimide(PI) Polyimide is a non melting high temperature polymer. Strength, dimensional stability, and creep resistance remain high even at temperatures above 260°C. Low wear rates combined with the ability to work under unlubricated...

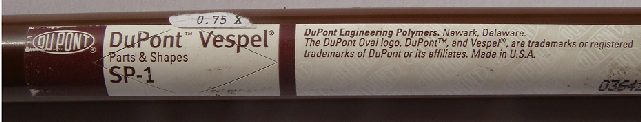

Brand:DuPont

Min. Order:1 Kilogram

Model No:DuPont Vespel CR6100

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:10000

Vespel® CR family provides excellent chemical resistance in refineries or chemical processing. They offer high-creep resistance for seals, run-dry capability for wear rings for pumps and easy machinability for tight-tolerance parts like ball-valve...

Brand:SIGRAFINE

Min. Order:1 Kilogram

Model No:SIGRAFINE® Die-Molded Carbon and Graphite

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:10000

The material class of die-molded carbon and graphite contains amorphous carbon as well as graphite and the so-called carbon graphite, a composite material containing both hard carbon and graphite. The materials have a fine to ultrafine granulation...

Brand:SGL

Min. Order:1 Kilogram

Model No:SGL Carbon Group EK 2200

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:10000

FeaturesGood mechanical strength, good sliding properties, high temperature resistance, high thermal shock resistance, low wettability, high corrosion resistance, high thermal conductivity, high purity, and good electrical conductivity.The SGL® has...

vespel® SP By DuPont - Vespel® SP Polyimide shapes (Vespel Sheet and Vespel Rods) manufactured by DuPont .DuPont Vespel is a brand of "sealing and wear solutions" for mechanical components and assemblies with unique properties that combine continuous operation at low to high temperatures, low wear in lubricated or non-lubricated environments and low friction at high PV with excellent creep, high strength and impact resistance, excellent dimensional stability, low thermal expansion and ease of cutting. stability, low thermal expansion, and ease of cutting to excel in demanding applications

DuPont Vespel SP-1 Polyimide Rods Field Applications

Vespel is the commercial name of thermosetting polyimide ( PI ) produced by DuPont, SP-1 is the conventional grade, pure PI.

Vespel is one of the high performance resins now available in the market and in mass production. It can be used under non-lubricated conditions (high PV value) at 10 times the height without affecting other materials, and therefore does not cause any harm.

DuPont Vespel is a typical representative of the polyimide (PI) plastic family.

VESPEL-SP1 (brown): Mechanical strength and electrical properties of the basic specification

Dupont Vespel® polyimide is available in five standard grades:

Vespel® SP-1 - Unfilled. Maximum strength & elongation: lowest modulus & thermal conductivity: optimum electrical.

Vespel® SP-21 - 15% graphite (by weight). Enhances inherent wear resistance, improves long term thermal stability.

Vespel® SP-22 - 40% graphite (by weight). Gives low coefficient of thermal expansion. Maximum creep resistance.

Vespel® SP-211 - 15% graphite and 10% teflon® fluorocarbon resin (by weight). Lowest static friction.

Vespel® SP-3 - 15% MoS2 (by weight). Best wear performance in dry environments.

Advantage of VESPEL SP series

Low coefficient of friction, good strength and impact resistance

High radiation resistance, high purity, low vacuum degassing

Inherent flame retardancy, good chemical resistance

Excellent electrical insulation properties, good cutting performance

Application of Vespel SP-1,Vespel SP-21

Since 1965, VESPEL® parts have been used in a wide variety of applications, finding VESPEL® products in aerospace, transportation, agricultural equipment, semiconductor processing, snowmobiles, and many other applications.

Aerospace, DuPont has over 40 years of experience serving aircraft engine parts as a global supplier of high-performance parts manufacturing

Transportation, DuPont products have extremely high PV limits and provide excellent wear resistance even when lubricated without oil or with minimal oil.

Electronics and semiconductors, DuPont VESPEL® S series components and profiles for electronic semiconductor components that require thermal stability, wear and low abrasion resistance, dimensional stability and consistent dielectric properties

Energy and material handling industries, where stable mechanical properties, low wear and low friction can be maintained at temperatures of 260°C for extended periods or briefly at 500°C, while withstanding a wide range of chemicals

HONYPLAS®PI poyimide material (chemical name is polyimide), Polyimide Sheet, Vespel SP-1 equivalent its standard semi-finished products include three forms of plate, bar and tube, all of which can be used for machining. In addition to the production of semi-finished profiles by compression molding, the direct molding process can also be used to mass-produce finished components, which is cost-effective.

HONYPLAS®PI Polyimide plastic is a non-melting high temperature plastic. It still has high strength, excellent dimensional stability and creep resistance above 260°C. It has low wear rate, high pV rate and can work under unlubricated conditions, so it is an ideal material for challenging friction and wear applications, which can significantly extend the service life of the application and reduce maintenance costs. High purity and low gas permeability also make it very suitable for vacuum, aviation and semiconductor industry applications.

HONY Offer Polyimide Sheets Pi :

Polyimide rod

Polyimide sheet

Polyimide pipe

Parts processed according to drawings

High-volume series parts produced using the direct molding process

Polyimide Block PI sheet Rod Feature

Non-melting high temperature polyimide

Long-term thermal stability at 300℃ for long-term use

(Short-term up to 400℃)

High heat resistance, up to 470°C (HDT/A)

Good low temperature performance, as low as -270℃

High strength, high modulus and high rigidity above 260℃

Excellent thermal and electrical insulation

High purity and low gas permeability under vacuum conditions

Good machinability

Inherent flame retardancy

Advantages of super high temperature HONYPLAS®PI poyimide polyimide (PI) polymers

◆High temperature resistance ◆Abrasion resistance

◆Resistance to deformation ◆Electrical insulation

◆Plasma, radiation ◆Ultra-low outgassing in vacuum

◆Excellent machinability ◆Resistant to chemicals, grease, oil and solvents

Application areas of super high temperature HONYPLAS®PI poyimide polyimide (PI) polymers

HONYPLAS®PI poyimide polyimide (PI) polymers has been widely used in automotive, semiconductor, office equipment, electronic and electrical equipment, scientific instruments, hot runner, petrochemical equipment, general machinery, textile machinery, laser printing, medical equipment and other fields.

◆Mold hot runner heat shield, heat insulation ring

◆Piston ring, valve seat

◆Chip test box

◆Copier separation jaws

◆Laser embossing rollers

◆Semiconductor chip nozzle

◆Semiconductor industry jigs and fixtures

◆Gas chromatography sealing ring

◆Rolling, sliding and thrust gaskets

◆Plasma torch vortex ring

◆Gear

◆Automotive engine gasket

◆Glass industry bracket

◆Microwave parts

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.